14.05.2018

WINTERSTEIGER at Xylexpo in Milan

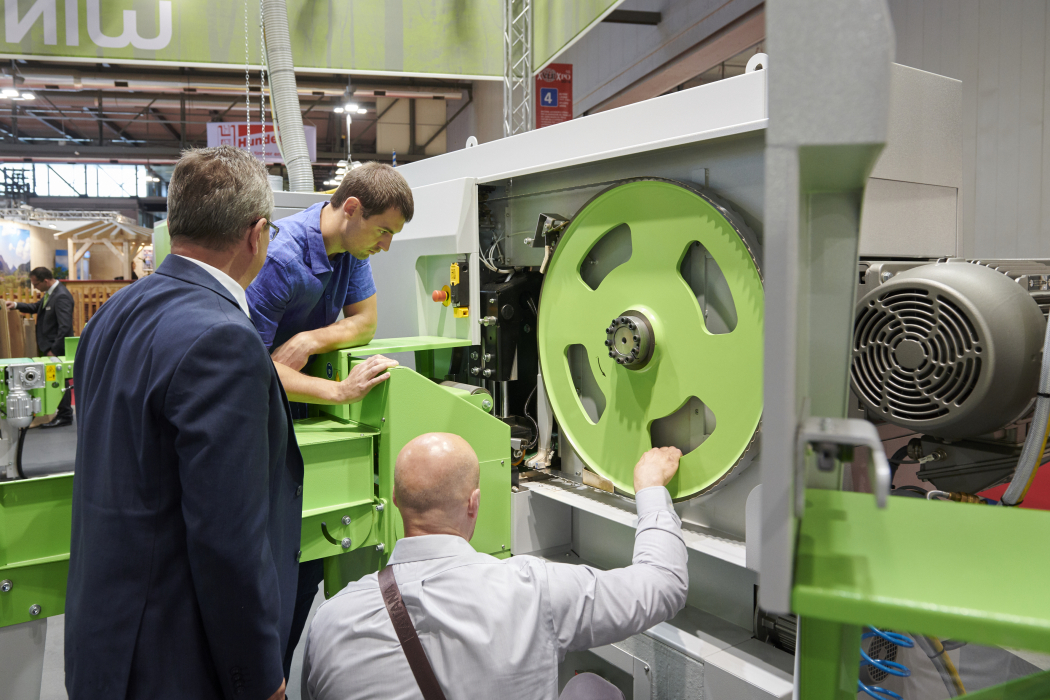

Cutting Demonstration at the new thin-cutting band saw DSB Singlehead NG XM

Cutting Demonstration at the new thin-cutting band saw DSB Singlehead NG XM

The Austrian machinery and plant engineering group WINTERSTEIGER AG presented its entire wood service range at this year's Xylexpo event. The items on display at the wood processing industry's international trade fair, which took place from May 8 to May 12 in Milan, covered everything from the company's thin-cutting technology and timber surface repairs to the high-quality saw blades that WINTERSTEIGER develops and manufactures itself.

NEW: Flexible thin-cutting band saw DSB Singlehead NG XM.

Flexibility and efficiency – these are the 2 main selling points of the new DSB Singlehead NG XM thin-cutting band saw. The machine was developed with changing customer requirements for timber cutting in mind, irrespective of timbers and applications. The result? The machine excels at both wet and dry cutting, with a cutting width of up to 350 mm and a maximum block height of 165 mm. It enables extremely thin lamellas from 1.3 mm to be produced with a kerf starting at 1.1 mm. The robust design and WINTERSTEIGER's years of experience in thin-cutting guarantee maximum machine availability while making the DSB Singlehead NG XM extremely efficient.

The DSB Singlehead NG XM can be extended from an individual machine to a multi-module production system. Up to 6 machines can be connected in series to extend the thin-cutting band saw to keep up with rising demand.

SHARE:

Demonstration of the new feeding magazine

Demonstration of the new feeding magazine

NEW: Feeding magazine – an easy way to boost efficiency.

WINTERSTEIGER offers the optimal solution for increasing efficiency and economy with the feeding magazine as an extension of band saws. Inserting multiple blocks of wood into the feeding magazine helps to eliminate interruptions in the workflow and the use of materials. It enables employees to operate multiple machines or run multiple work processes at the same time. The feeding magazine and the thin-cutting band saw work together perfectly: Combined software controls prevent operating errors – the feeding magazine adapts to the feeding speed of the machine. It is very easy to set different block heights mechanically.

DSG Notum thin-cutting frame saw: reliable and efficient.

More than 40 years of experience were packed into the DSG Notum thin-cutting frame saw. There are already over 2,000 WINTERSTEIGER thin-cutting frame saws in use around the world, and in showing the DSG Notum, the company will be exhibiting an efficient saw that is able to produce ultra-thin kerfs starting at 0.7 mm. Other strengths of this system include excellent component access thanks to the open machine construction, a touch screen, which makes it easy to operate, and the wide range of services it offers.

Timber Repair & Cosmetics.

WINTERSTEIGER's Timber Repair & Cosmetics systems, which include both semi-automatic and fully automatic timber surface repair machines, have been a successful part of the company's product range since 2012; they enable the company to meet the high demand for rustic wooden lamellas. WINTERSTEIGER will be showcasing the TRC-M Easy at Xylexpo. The semi-automatic machine may be used as an entry-level timber surface repair model, or alongside the TRC 3000 to correct either customized products or products with unusual (e.g. larger than normal) sizes.

Saw blades developed and manufactured by WINTERSTEIGER itself.

WINTERSTEIGER's stand at Xylexpo would of course not be complete without the thin-cutting saw blades developed and manufactured in-house. They are designed to meet specific and individual customer requirements perfectly and make WINTERSTEIGER the complete provider.

Machines and plants from a single source.

If customer-specific production systems are needed, then the automation expertise of the WINTERSTEIGER group – provided by VAP Gruber Automations GmbH – is at hand. WINTERSTEIGER and VAP Gruber Automations provide automatic thin-cutting band saw systems and special systems for multi-layer products, as well as automatic timber repair systems for restoring timber surfaces with the TRC (Timber Repair & Cosmetics) product line.