04.02.2017

New automated ski servicing machine at ISPO

WINTERSTEIGER AG will be exhibiting a new machine at ISPO in Munich, the largest sports equipment trade fair in the world. WINTERSTEIGER, the specialist machinery manufacturing company from Upper Austria will present the Scout – an automated ski grinding machine for base and edge grinding.

The new Scout, which will celebrate its European début in Munich, is an automated ski grinding machine for base and edge grinding. Thanks to its compact design, this machine will even fit into small workshops, making it possible to switch from manual servicing to automation. One operator using the Scout can achieve almost double the throughput of one operator using two manual machines.

Furthermore, the Scout is a very compact machine: it has the smallest footprint of any automated unit and is shorter than comparable machines. All the functional units are accessible from the front, allowing the Scout to be installed directly against a wall.

SHARE:

Better service processes, higher service quality.

Stone and Disc modul

Stone and Disc modul

The Scout speeds up and improves the service process. Automation allows a higher throughput – approximately 15 to 20 skis can be serviced per hour. There is less manual handling required making the workshop processes even smoother. Personnel requirements are reduced by about 50% compared with manual machines, while grinding quality and repeatability remain constant, regardless of the operator. Another advantage over manual servicing is that the settings can be saved and service results reproduced.

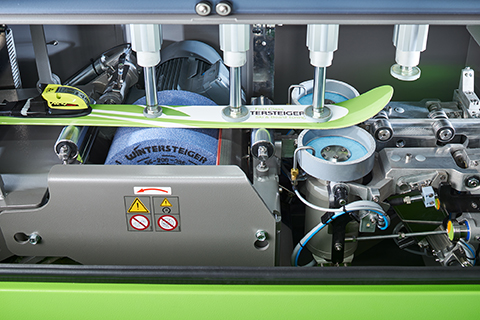

The two main players: stone and disc.

Inside the Scout is proven Wintersteiger technology: the stone module for the base and the disc for the edge. The stone module grinds precise base structures evenly over the full length of the ski, right to the tip. With a stone width of 200 mm, all types of ski can be processed. The disc module is used to work the side and base edge. Even ski manufacturers and racing departments use Ceramic Disc Finish technology, which produces accurate edge geometry, precise grinding angles, smooth edge surfaces and consistent grinding quality.

Safe and easy to use.

Safe and easy to use.

Safe and easy to use.

The closed operating system improves safety in the workshop, while also making the working environment quieter and clean. Binding bridges and pre-sorting of skis are eliminated because the Scout uses cylinders: it recognizes the ski length automatically and sets the cylinder to the position that will give a perfect result. Clear user guidance is provided and it is easy to set the grinding parameters – for novices as well as experts.

The Scout can also be customized to individual needs. Two loading systems for loading single skis or in pairs as well as options such as the performance package are available.

Bootdoc: products for enhanced comfort.

3D Foot scanner Vandra and Heat Socks

3D Foot scanner Vandra and Heat Socks

WINTERSTEIGER sells boot fitting products for end consumers under the Bootdoc brand. At the ISPO in Munich, the innovations presented by the company will include the Vandra 3D foot scanner. This 3D scanner provides a three-dimensional image of the feet as well as measurement data such as ankle circumference, instep height and foot length. With the aid of this data, sales staff can quickly find the right ski boots and insoles – the 3D scanner thus supports the sales process.

Another highlight at the trade fair are the XLP One Heat Socks. These Power Fit Socks support the foot and also ensure that your feet stay warm. Power is supplied to the integrated heating element by high-performance lithium-ion rechargeable batteries, and the controls for the four levels of heating output are directly on the battery pack. WINTERSTEIGER is constantly expanding its Bootdoc product range, with recent additions including a heated ski boot bag.

Record turnover to start the New Year.

In 2015, the sports business segment of WINTERSTEIGER AG, based in the Innviertel region of Austria, achieved a record turnover – but this achievement was surpassed in 2016. "All our product groups have experienced very positive development," says Head of Sales Daniel Steininger, "even though the order numbers at the start of the year – after three consecutive winters with very little snow – looked as if they wouldn’t break any records."

Heading the product portfolio – WINTERSTEIGER supplies a full range of products for sports equipment retailers and ski rental – are its automatic ski servicing machines: more than 70 new machines were installed worldwide in 2016. Another top seller is the Easyrent rental software, which gained many new customers for the second year in a row.

WINTERSTEIGER was able to achieve its budget targets in nearly all its markets and attributes its success to the fact that existing customers value the reliability and quality of its products and services and are happy to choose Wintersteiger again. These positive references then convince new customers. Another factor in its success is the growing professionalism of the ski rental sector: sports equipment retailers are optimizing their rental processes and investing in machines, rental systems and software.