04-03-2017

WINTERSTEIGER Classic: Optimizations for growing requirements

The WINTERSTEIGER Classic has for many years been the tried-and-tested, universally flexible and best-selling plot combine for mix-free harvest. Hundreds of satisfied customers around the world value and stand as testament to its quality and reliability.

Harvesters are however being used ever more intensively and are deployed for harvesting for a higher number of days than before, meaning the demands placed on them are also increasing. WINTERSTEIGER is meeting this trend head on and has optimized numerous aspects of the Classic.

SHARE:

The service life of all drive belts has been examined together with a notable belt manufacturer. Based on the findings concerning wear patterns and behavior when subject to extremely heavy usage, the belts have been replaced in favor of significantly higher-quality alternatives with even more durable qualities.

The wearing behavior of the pulleys was tested and they have now had a hard coating applied that significantly increases their resistance to wear.

All Classic plot combines will now be delivered with these V-belts and pulleys. It goes without saying that they can be simply installed in existing machines at any time!

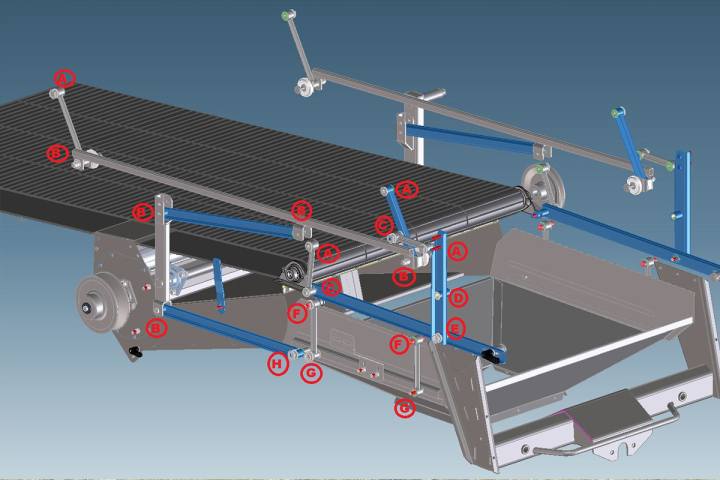

The swing arm bearings of the shakers and sieve boxes are subjected to significant loads by superposed vibrations. Extensive analyses in this area together with a notable friction bearing manufacturer have shown that high demands and long operating hours can cause increased wear. For this reason, higher-quality friction bearings with a significantly longer service life are now being installed.

In the course of this improvement, other bearing locations that are subjected to high loads (e.g., engine drive, intermediate transmission, blower drive, reel control) are being changed to extremely high-quality versions.

Once again, all new Classic models are being fitted with these bearings while existing machines can be upgraded.

As well as the harvest, long transport distances between several locations over rough ground can place particular stress on components.

Measures have therefore been implemented for the cutting units. As is usual for conventional combines, they are now fitted with a bladder accumulator to significantly dampen vibrations and reduce the load on components. The bearing and attachment of the reel bracket has also been reinforced, while mechanical reinforcements have been made to the main frame. The bladder accumulator and the reel bracket reinforcement are already built into all newly delivered machines.

To dramatically increase maneuverability in breeding nurseries, the Classic is also available with a shorter wheelbase of 1,430 mm instead of the standard 2,300 mm.

In addition to those already mentioned, a number of other measures have been taken to meet the increased durability demands on the Classic.

It was particularly important during this project that the improvements could be retrofitted to existing machines. As a result, the belts and pulleys will be automatically and exclusively replaced with the higher-quality versions during a regular machine service.

If you are interested in upgrading, please contact your customer service technician. They will be happy to help you.