From frame saw to circular saw to band saw

DSG 200 frame saw

DSG 200 frame saw

The first high-performance thin-cutting frame saw was developed in 1998: the DSG 200, with a few modifications, is still in the product range today. The big advantage of frame saw technology is its cutting accuracy. On the other hand, however, there is a low throughput – a new technology was needed! Two options were considered to increase efficiency: the circular saw and the band saw. Band saw machines for the thin-cutting of wood already existed, but they did not cut very accurately and a lamella less than 2-mm thick was not possible.

Too smart to be true.

Mach 1.4 thin-cutting circular saw

Mach 1.4 thin-cutting circular saw

Too smart to be true.

The question of better saw technology divided colleagues into proponents of the circular saw associated with development manager Erwin Sturmair and into the pro-band saw group with designer Reinhold Mayr. Initially, the circular saw technology was pushed and the Mach 1.4 thin-cutting circular saw marked the start of an extensive development project. Six circular saw modules ran in succession and seven lamellas could be manufactured at the same time. The expectations of the new saw were high – short setup times and a capacity of 1,000,000 m2 per year in two-shift operation were promised to customers.

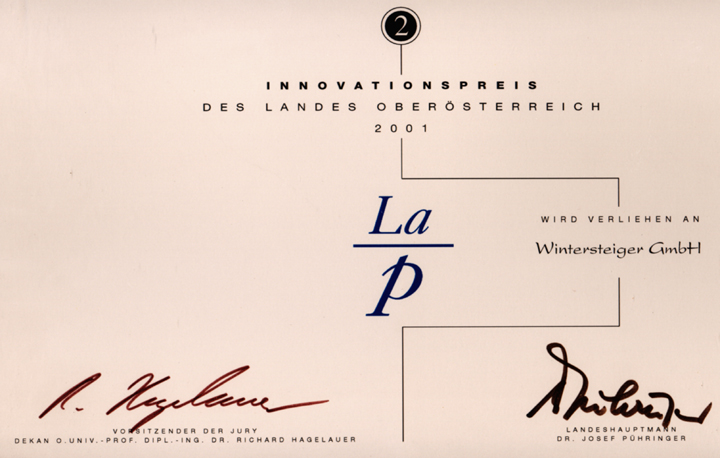

Upper Austria State Prize for Innovation

Upper Austria State Prize for Innovation

The circular saw did, however, present the team of developers with some challenges. On one hand, the cutting height: the six saw blades came from the bottom and the cutting height was therefore limited to 80 cm. Another challenge was the saw band guide, as the saw blades were stabilized with air cushions so that the friction on the guides did not cause the saw to overheat.

In total, four Mach 1.4 circular saws were built and sold. In 2001, WINTERSTEIGER even received the Upper Austria State Prize for Innovation for this saw! However, the guide problems could never be solved effectively and in the end WINTERSTEIGER decided to use the "right" saw technology: the thin-cutting band saw.