04-19-2023

Ligna 2023: WINTERSTEIGER brings “World of WOODTECH” to Hannover

For this year’s Ligna trade fair, the Upper Austrian company WINTERSTEIGER AG has hired three stands with a total surface area approaching 900 m2: The machine and plant engineering company touches down in Hannover with six machines for the thin-cutting of wood and processing of wood surfaces as well as two new saw blades. In the outdoor area, three SERRA sawmills are doing live demonstrations, with information on automation solutions in sawmill technology completing the offering.

- Thin-cutting band saws ranging from entry-level models to high-speed solutions as well as the tried-and-tested DSG Notum thin cutting frame saw (hall 27, stand F60)

- TRC machines for automated precleaning and repair of wood surfaces (hall 27, stand F60)

- New saw blades for improved efficiency and longer tool life

- Automation in sawmill technology (VAP-WINTERSTEIGER, hall 25, stand N25)

- Mobile and stationary sawmills (SERRA GmbH, part of the WINTERSTEIGER Group, stand N25 in hall 25 and outdoor stand FG K52)

SHARE:

Precision Thin-Cutting of Wood for Every Need.

The company’s slogan is “Discover the World of WOODTECH”. With this world continuing to grow, WINTERSTEIGER boasts a wide range of products for wood working and processing, including customized automation solutions.

WINTERSTEIGER has four machines for precision thin-cutting of wood on display at Ligna. The newest model is the DSB Twinhead Pro XM thin-cutting band saw for high capacities. This band saw with two saw models was developed for precision cutting of hardwood and softwood in the dry and wet cutting process and stands out as a high-speed option. Another plus point is that it is digital: By connecting the machine to the myWINTERSTEIGER cloud, it offers automatic bearing monitoring for preventative replacement, automatic block width measurement, and relevant plant data collection.

With its DSB Compact XM, the Innviertel-based company is showcasing the entry-level model for the precision thin-cutting of wood. The third band saw machine, the DSB Singlehead NG XM, falls between the first two in terms of capacity. The unique feature of this DSB Singlehead is its 400 mm cutting width: This model was originally manufactured at the request of a customer and has been in high demand ever since, with the machine now being included in the brand’s standard product range.

Not forgetting frame saw blade technology for the most economical thin-cutting.

The DSG Notum thin-cutting frame saw is also on exhibit – with over 200 machines sold across five continents, this model is a true success story.

New: TRC Preclean for Automatic Precleaning.

TRC Preclean for automatic wood surface precleaning is a new addition to our product range: Before repairing defects – by filling – raw planks need to be pre-cleaned. The TRC Preclean removes bark inclusions or soft parts from knotholes, while cracks or similar defects are cleaned. The system scans the defects, evaluates the data, and processes these areas. The processing of two clamping tables allows loading and unloading, scanning, and evaluation to be carried out while defects are being cleaned. The TRC Preclean can be upgraded with additional modules and can process plank layers and boards up to 2,500 x 1,300 mm.

Another highlight at Ligna is the high-performance TRC Board for the automatic repair of defects in wood. The application units work in tandem to repair defects in top layers, engineered wood flooring, solid wood flooring, finished planed timber, and much more. Wood dimensions: length: 500–3,000 mm, width: 100–350 mm, depth: 3–30 mm

New Saw Blade Products.

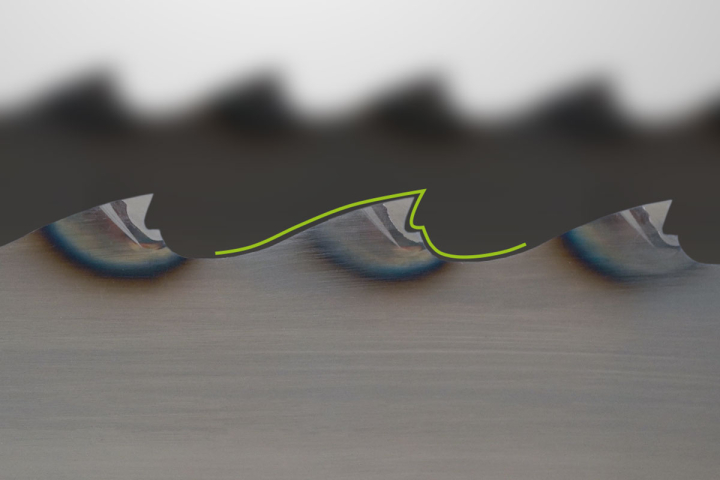

Prime X-Dust

Prime X-Dust

New Saw Blade Products.

WINTERSTEIGER offers a one-stop shop for machines and tools and WINTERSTEIGER Sägen GmbH in Arnstadt, Thüringen, is continuously developing its range of saw blades. The team is presenting two brand new saw blades at Ligna: The Prime X-Dust saw blade for thin-cutting band saws has been optimized for softwood. The Carbide is also a new addition, ensuring longer tool life and better efficiency in the sawing process.

Indoors and Outdoors: Sawmill Technology from SERRA.

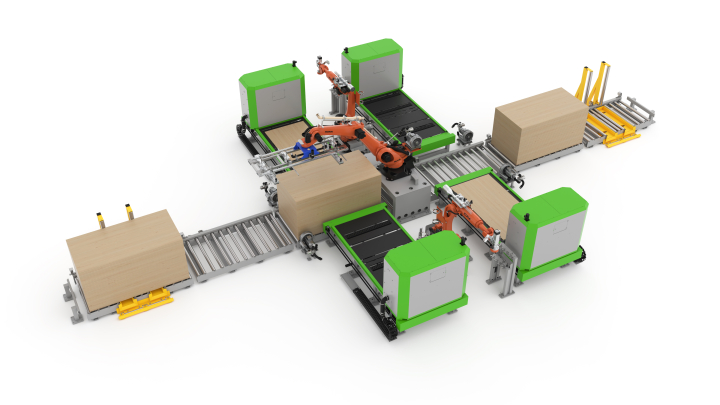

Machine manufacturer SERRA has been part of the WINTERSTEIGER group since January 2019. In hall 25, the team will be presenting various saw modules for trunks with a trunk diameter of up to 160 cm, the CS 600 circular resaw, and the Shark 200 precision sharpening machine. Also represented at the stand: the VAP WINTERSTEIGER team with information on the latest automation technology in the sawmill industry.

Mobile and Stationary Sawmill Systems and Small Sawmills.

In the outdoor area, SERRA will be demonstrating the SERRA KE90 mobile sawmill with a 7 m cutting length including ejectors and unwinders for the side or board and main goods.

From the range of stationary sawmills, the XE135 with a 7 m cutting length has been assembled for display, as has a log loader with three strands for feeding the logs and push-back system. After the push-back, the cut goods are conveyed to a 3-way sorting table via a conveyor belt integrated in the base frame. The operator decides which direction the next board will be conveyed in using a preselector switch: The side goods reach the SERRA-Quartett double edger via cross conveyors and roller conveyors, while the main material is cut into slats in the CS600 multi-blade saw with a 45 kW main motor. After it has passed through the machine, it is then separated.

Also in operation are the small FE50 sawmill and the “Iron Horse”, a highly maneuverable machine with a wide chain drive for moving logs outdoors.

Seventy Years of WINTERSTEIGER.

This year the Ried in Innkreis-based machine and plant engineering company celebrates its 70th anniversary and can look back on a very successful company history full of innovative drive. The segment for the thin-cutting of wood originated in 1970, when Hans WINTERSTEIGER developed the first thin-cutting band saw for cutting wood wedges for ski production.