DSB Twinhead Pro XM

Thin-cutting band saw

DSB Twinhead Pro XM Thin-cutting band saw

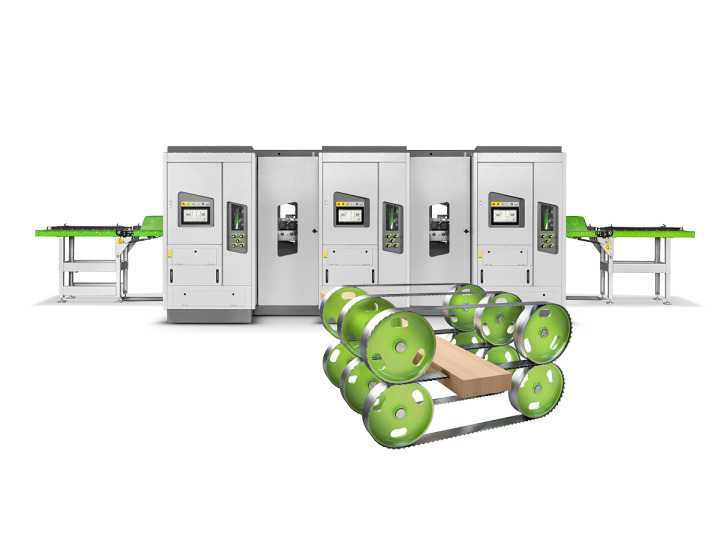

Thin-cutting band saw with 2 saw modules.

DSB Twinhead Pro XM Thin-cutting band saw

Thin-cutting band saw with 2 saw modules.

Developed for precise cutting of hardwood and softwood in the dry and wet cutting process.

The proven DSB Twinhead NG XM thin-cutting band saw has been further developed to produce a "Pro" version that is setting new benchmarks in the precision thin-cutting of wood. With its digitalization features, the DSB Twinhead Pro XM belongs to the next generation of machines. The remote maintenance package includes connection to the myWINTERSTEIGER cloud. Bearing monitoring, automatic block width measurement, automatic saw blade detection - all machine data are clearly visualized. Other technical highlights include optimized machine accessibility for maintenance and cleaning, the 12-inch multi-touch display with completely overhauled user interface, powerful chip extraction, and much more.

Machine data for continuous improvement.

Digitalization has heavily influenced mechanical engineering in recent years. It brings with it enormous opportunities and possibilities, with data being the most precious jewel of the 21st century. However, collecting data is only the first step. Only through sound analysis and interpretation can the true gems be unearthed. If this is achieved, added value is available that provides a clear advantage. WINTERSTEIGER is focusing on digitalization in machine development and is working full steam ahead on new solutions. In addition to machines, we also develop the appropriate software: our proximity to our customers means that these are developed with flexibility and continuously adapted on an ongoing basis.

Optimized for the production of hardwood and softwood products

in the following product categories:

- Engineered wood flooring

- Multilayer boards

- Glue-laminated wood

- Doors

- Windows

- Furniture

- Pencil boards

- Ski/snowboard components

- Musical instruments

- Saw mill - secondary cut

- Rotor blades for wind farms

Your benefits summed up

Digital solutions for efficient production processes (in the remote maintenance package)

- Saw blade detection in the machine for automatic tool management

- Automatic block width measurement

- Automatic bearing monitoring for preventive replacement

- myWINTERSTEIGER cloud connection

- 12-inch multi-touch display for optimum usability

High performance and maximum dimensions

- 2-module basic configuration can be expanded to form a complete production system

- Cutting width up to 310 mm, block height up to 165 mm, and feed speed up to 45 m/min

- Optimized accessibility for easy maintenance and repair

Premium technology for maximum precision

- Unique feed system for all block characteristics

- Optimized for cutting softwood

- Powerful extraction for high feed speed

- Everything from a single source and perfectly harmonized:

- Machine, tool, automation, and reliable customer service - available to you across the globe

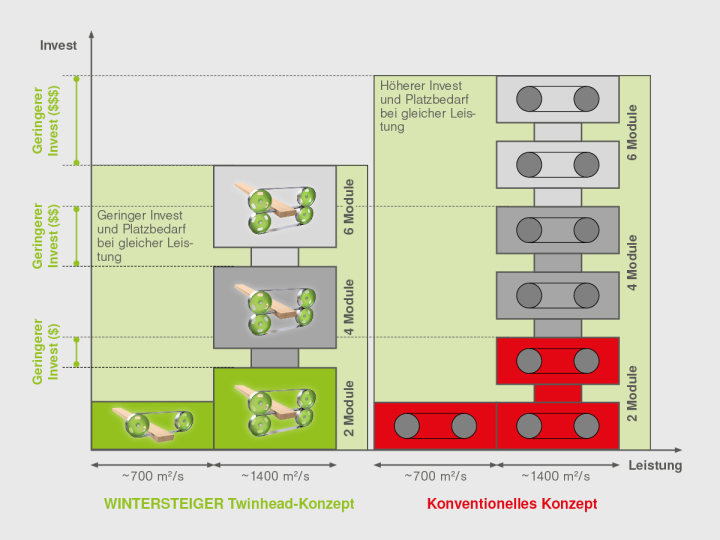

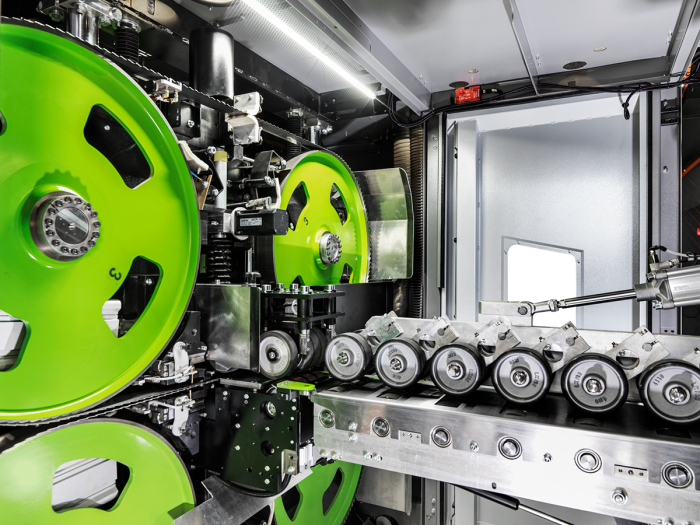

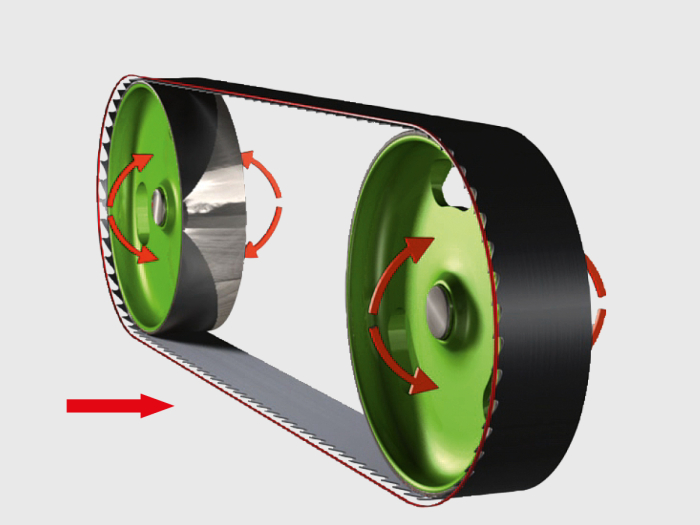

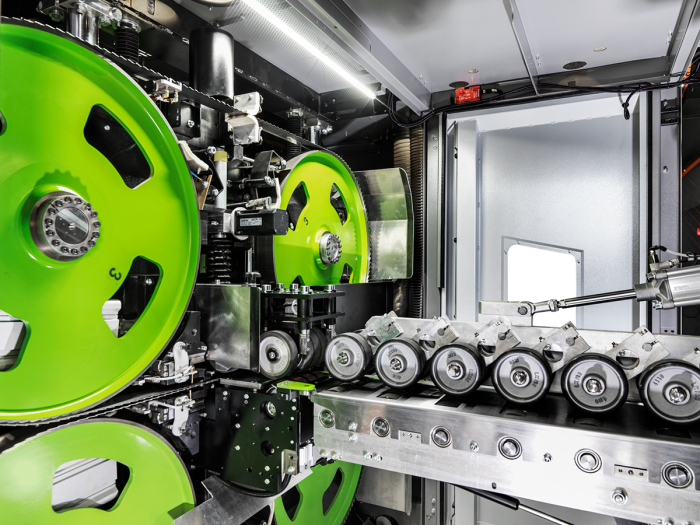

Double = better grip: the Twinhead concept

Save space with horizontal saw modules.

The DSB Twinhead Pro XM thin-cutting band saw features two saw modules in the basic version and is the most compact solution for performing two cuts. The Twinhead concept, namely the parallel arrangement of the saw modules, is the optimum solution wherever multiple cuts are required.

The servo-driven module adjustment via precision threaded spindles allows up to 10x faster height adjustment. You therefore achieve quick and optimum utilization of the cutting height.

Cutting width up to 310 mm, block height up to 165 mm.

The tried-and-tested block transport system of the predecessor model has been adopted and optimized for the DSB Twinhead Pro XM. The maximum block clearance height is 165 mm, with a cutting height of up to 165 mm. Depending on the configuration, the DSB Twinhead Pro XM's feed speed is infinitely variable up to 45 m/min.

Unique price/performance ratio.

Even the basic configuration of the DSB Twinhead Pro XM - with its ergonomic advantages and minimum space requirement yet maximum performance - is a highlight. The Twinhead concept with two saw modules in one machine keeps the costs of investment within comfortable limits.

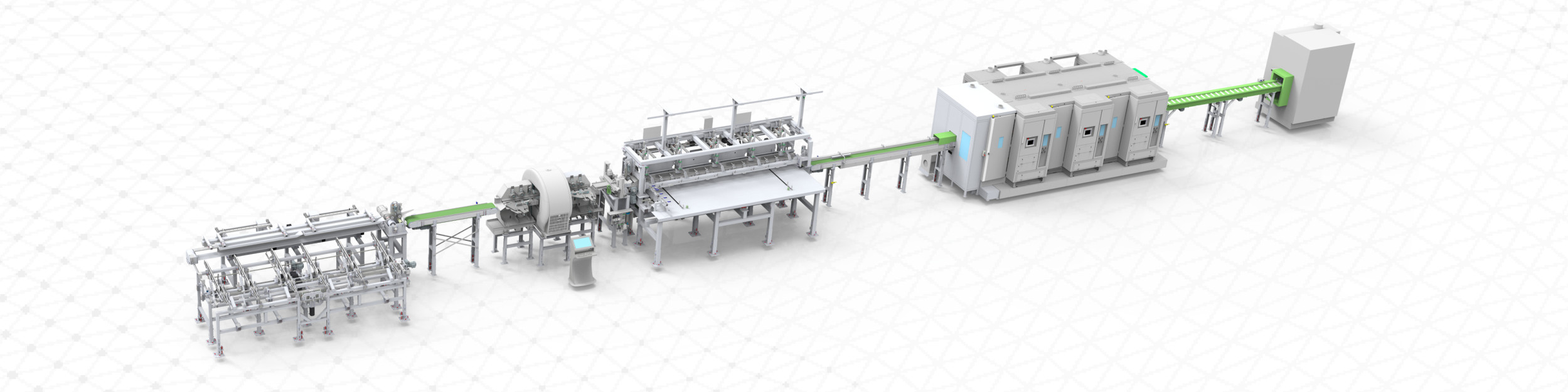

For maximum capacity requirements: your machine grows with you!

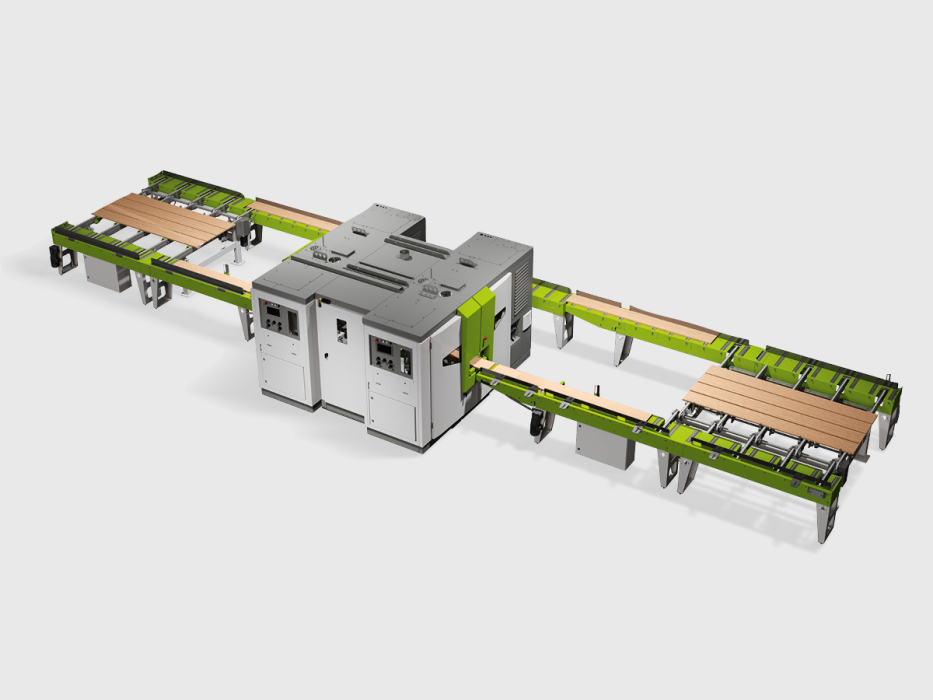

Automation and integration.

The DSB Twinhead Pro XM can be expanded: machines connected in series are designed as whole production systems to form complete manufacturing units with a compact design. Existing machines and systems can be expanded at any time.

The automation and integration of machines to form individual process solutions are among WINTERSTEIGER's core competencies.

Optimum accessibility for easy maintenance and repair.

The innovative design of both machine and serial installation ensures that all saw modules and machine components are optimally accessible while requiring minimum space.

These special ergonomics minimize both time and cost required for setup, configuration, and changing of saw bands. This concept also provides full access to the room within the machine.

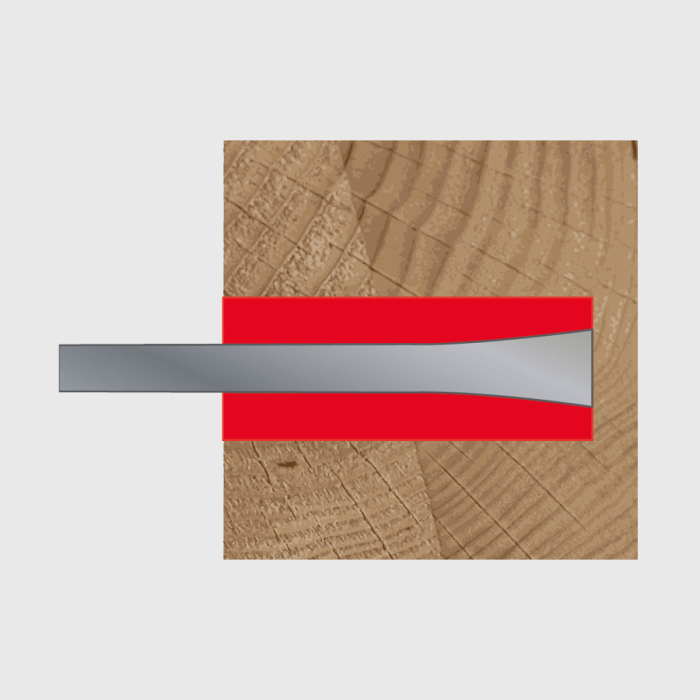

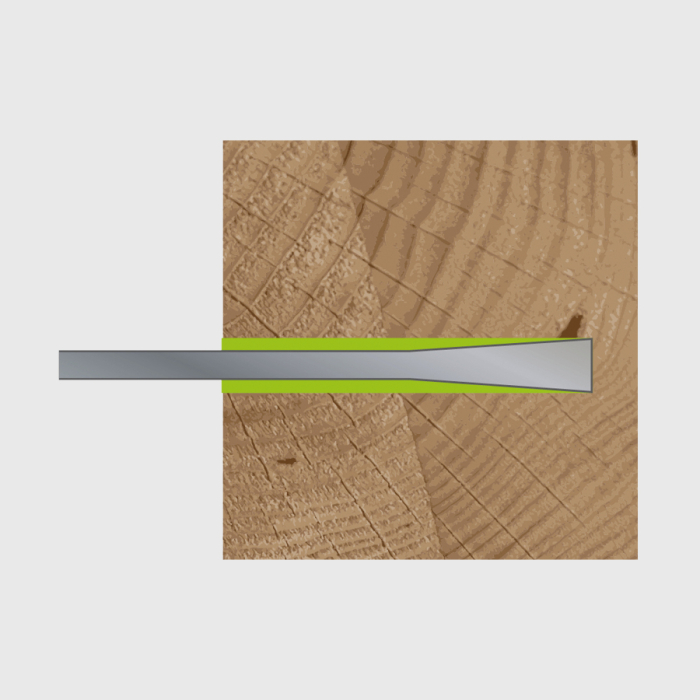

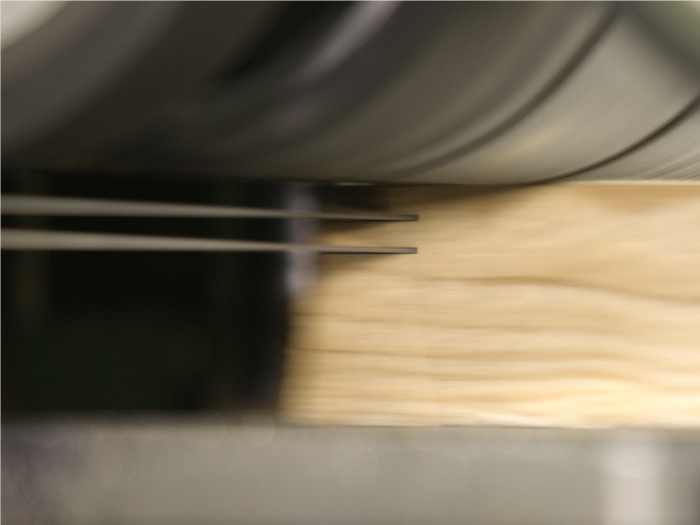

WINTERSTEIGER thin-cutting: maximum precision - minimal kerf

Cutting-edge sawing technology for maximum precision.

Instead of simply overstretching the band-saw blade, WINTERSTEIGER uses automatic band tracking control to keep the band-saw blade in position on the deflection pulleys: in addition to protecting and retaining the inner saw band tension, the gliding surface on the deflection pulleys is also protected.

Combined with the carbon guides, this optimal saw blade tension allows for aggressive positioning of the saw band guides. As a result, the saw band tension is concentrated in the cutting area.

The unique technology package, in combination with the rigid block guide, ensures maximum cutting precision when using minimum cutting kerfs starting at 1.1 mm.

Your gain:

up to 40 % greater timber yield!

Regular cutting with increased loss caused by a lack of precision.

WINTERSTEIGER thin cutting with minimal cutting loss and maximum precision!

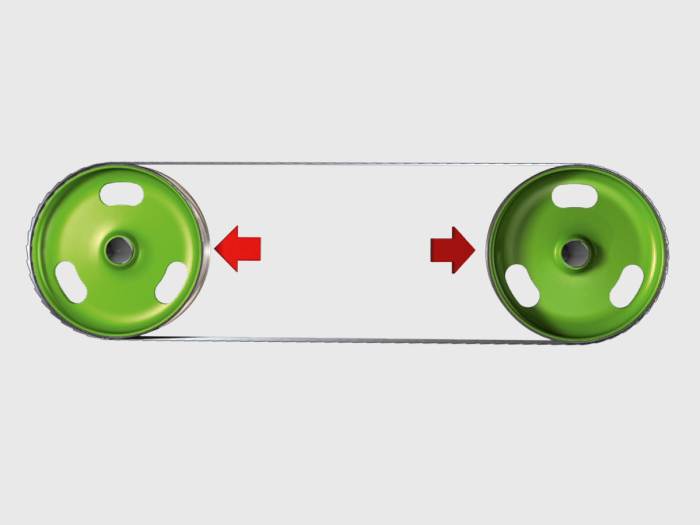

Unique feed system for all block characteristics.

Unique feed system for all block characteristics.

Driven transport rollers above and below guarantee continuous block transport, even when faced with extreme workpiece characteristics. The specially rubberized transport rollers and the innovative counter-pressure system guarantee optimum grip as well as minimum friction for wet or dry material. At the same time, the hard chrome-plated supporting table ensures that the workpiece is as stable as possible (optimally aligned).

The transport rollers are electronically controlled and infinitely adjustable at the infeed and outfeed (1 - 18 m/min or 8 – 45 m/min). The vertical stabilization of the workpiece in the cutting area is the basis for the perfectly precise cut.

Additional driven pressure rollers immediately above the cutting area guarantee the constant stability of the workpiece across its full width. This gives you the ability to cut not only pre-planed material, but also uneven and rough-cut wooden blocks with longitudinal or latitudinal deformations or that are torsion-warped or cupped.

Wooden blocks with longitudinal/latitudinal deformation, cupped or torsion-warped

Wooden block dry cutting

Wooden block wet cutting

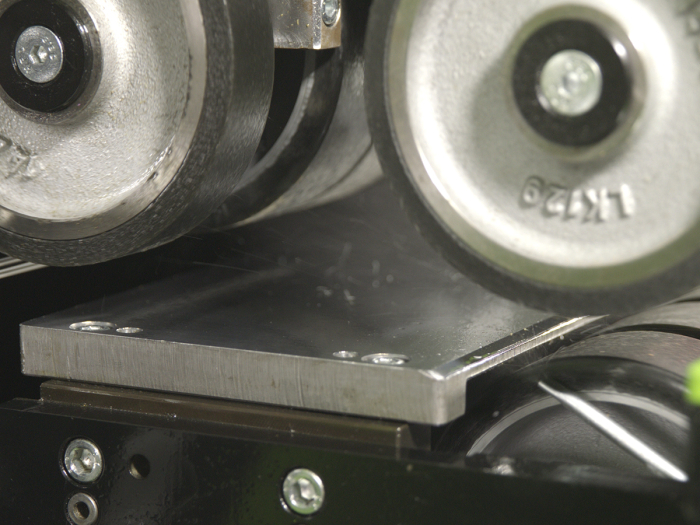

Automatic band tracking control.

When cutting non-homogeneous materials such as wood, the saw band is exposed to different cutting forces. The automatic band tracking control uses a sensor to detect the displacement of the saw band caused by differences in cutting force. An adjusting mechanism driven by an electromotor controls the deflection pulleys and guarantees optimum positioning of the saw band. This prevents the saw band running off the deflection pulley.

Servopneumatic saw band tensioning.

A servo valve controls the saw blade tension, which is adjusted to match the saw blade dimensions. During idle periods, the tensioning pressure is reduced to protect the saw band.

High-tech carbon guide.

This high-tech composite material made of abrasion-proof carbon fibers and heat-resistant epoxy resin guarantees precise band guiding and an extremely long lifetime.

Powerful chip removal.

The machine extraction is designed so that chips are removed from the machine as quickly and efficiently as possible. This prevents temperatures from becoming too high inside the machine. Primarily in the softwood segment and at high feed speeds, where more chips accumulate in a shorter time, optimized extraction is a clear benefit.

Discharge screw

The tried-and-tested discharge screw is now also used in the DSB Twinhead Pro XM, the largest machine in our product portfolio. It ensures that chips are continually removed from the machine interior. It also provides support during machine cleaning: chips can easily be swept into the discharge screw.

Think digital

Modern solutions for more efficient production processes.

Unplanned downtimes cost time and money. Sensors that monitor the DSB Twinhead Pro XM provide the solution for reducing downtimes.

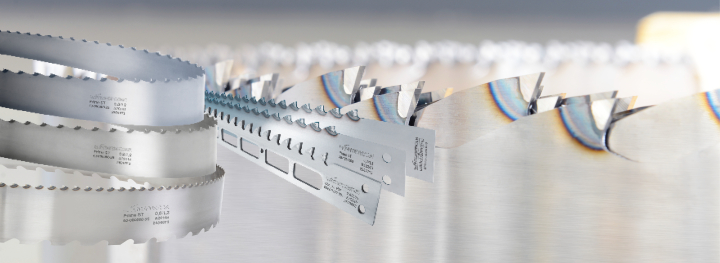

Digital saw blade detection simplifies tool management. The inserted saw blades are detected when the machine is started, and the tool and machine data are linked to one another. Aside from the type of wood and customer-specific data, data no longer have to be entered manually due to automatic detection.

For detection purposes, the WINTERSTEIGER saw blades are already clearly marked in the manufacturing process. The sensor technology on the machine then detects the saw blades and every saw blade can be clearly identified as a result. The rest of the cutting process is not affected in any way.

Optical sensors detect the block width automatically and it no longer has to be entered manually. The throughput can also be calculated with this measurement, the advantage here being that you always have an overview of the production volume.

The condition of the main bearings is documented during bearing monitoring and the sensors enable conclusions to be drawn about the wear on a bearing. If sufficient data are available, bearing damage can be anticipated: preventive bearing replacement can be carried out outside of production time and without interruption due to unforeseen damage.

WINTERSTEIGER has been relying on remote maintenance for many years. This allows for a very quick response should support be required. This online support means that companies can often avoid the need for a WINTERSTEIGER customer service technician to be deployed to their premises.

The remote maintenance package also includes the myWINTERSTEIGER cloud connection. All machine data are stored in a structured way in this cloud and are available for analysis.

Options for every requirement

The DSB Twinhead Pro XM delivers what it promises, and provides options which further improve the result depending on individual needs.

Optimum feed for every application.

The DSB Twinhead Pro XM facilitates high-speed feeding of 8 to 45 m/min for high-performance applications in the highest capacity range. For standard, precision, or special applications for sensitive materials or XXL dimensions, the standard feed from 1 to 18 m/min can be selected.

Innovative spraying system for wet cutting.

Spraying the saw tooth with a special, highly wood-compatible spraying agent creates a vapor that lubricates and cools the saw bands. The spraying intervals can be customized according to need and application. The benefits here are an improved service life of the thin-cutting saw band thanks to reduced friction and the prevention of resin deposits. The benefits of the spraying system are particularly evident when cutting wet wood. However, it also demonstrates its performance in applications involving the cutting of wood types with a high resin or silicate content.

Lubrication of the drive pulleys and spraying during the cutting process.

The system for the lubrication of the drive pulleys and spraying during the cutting process has been overhauled. In the standard version, two separate lubrication tanks are available: one for lubricating the drive pulleys and the other for spraying during the cutting process.

Additional spraying with water.

As an alternative to conventional spraying agents, water is also well-suited for the processing of certain kinds of wet wood. A small amount is sprayed on the tooth tips and loosens the mass of wet sawdust, resin, and lubricant. The lateral clearance angles of the saw therefore remain clean and functional. Water as a spraying agent can be combined with conventional agents or employed separately as needed.

Quick help.

With the WINTERSTEIGER remote service.

Quick help.

With the WINTERSTEIGER remote service.

Quality and speed are the deciding factors in the event of a breakdown. WINTERSTEIGER sales and service networks guarantee optimum support in case of technical queries and fastest possible support by professional service technicians.

In addition, to improve availability and reduce response times, you also have the option of equipping your WINTERSTEIGER thin-cutting band saws with remote service. You are always only seconds away from professional troubleshooting with WINTERSTEIGER remote service. Your machine's online connection is the direct link to our Technical Customer Service. Error detection and diagnosis are done almost in real time, along with data analyses, optimizations, and service measures. WINTERSTEIGER remote service works with LAN/WAN/GPRS/UMTS/HSDPA.

Your benefits:

- Increased machine availability

- Shorter downtimes thanks to remote diagnosis

- Reduced maintenance costs

- Routine transmission of current software updates

- Data backup and secure spare part identification

- Support of maintenance staff and service crew

- Machine downtime is avoided

Our services:

- Provision of the hardware (router)

- Registration on the WINTERSTEIGER remote service portal

- Free remote service for the first year (service can be extended by maintenance agreement)

WINTERSTEIGER after-sales service.

When the delivery ends the support begins.

WINTERSTEIGER after-sales service.

When the delivery ends the support begins.

The best time to evaluate the quality of an investment is several years after delivery. For this reason, WINTERSTEIGER has an after-sales service that is available to you all over the world.

- Commissioning and training

- Production support

- Proactive maintenance

- Blanket orders for consumables and saws

- On-call help desk.

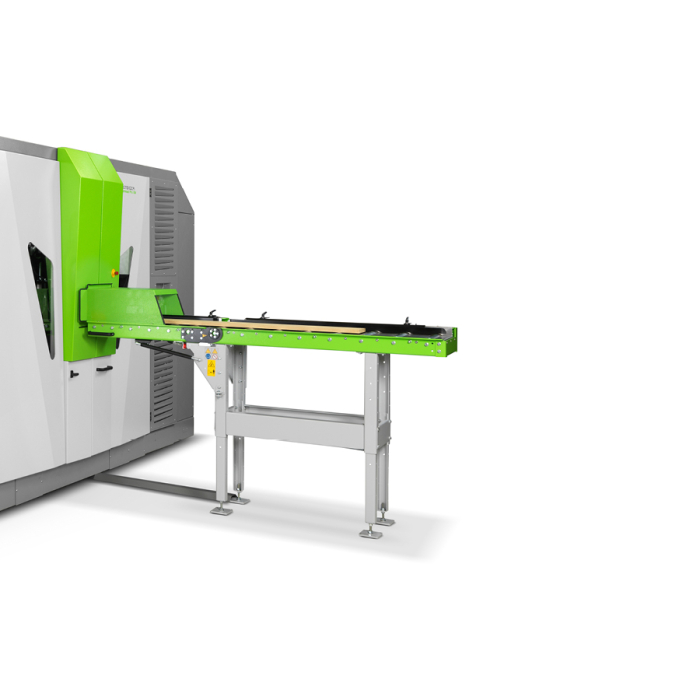

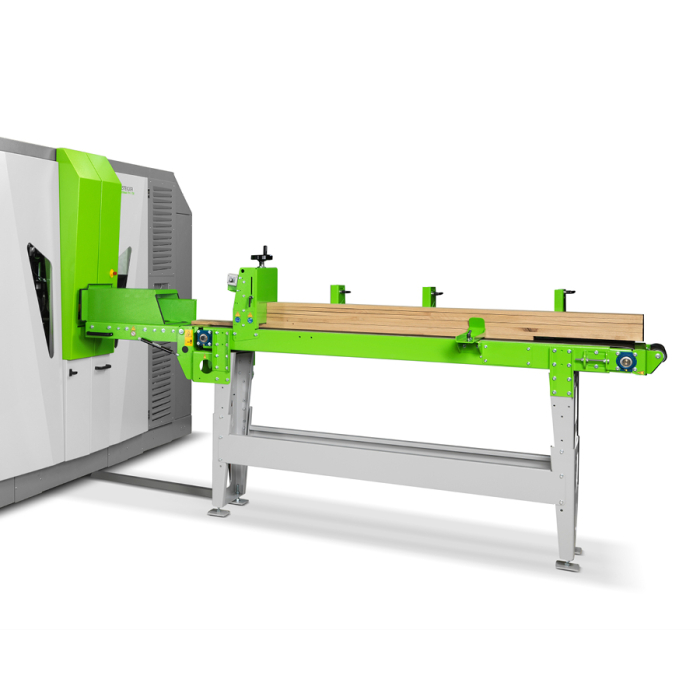

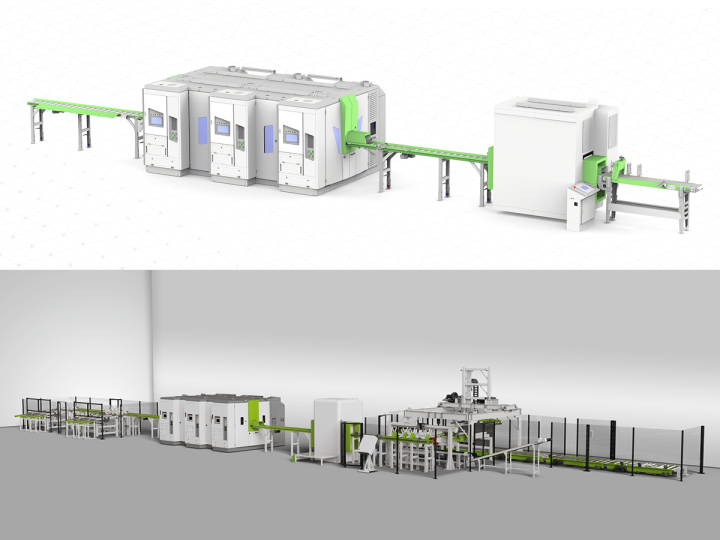

Conveyor systems – the right solution for everyone

In addition to machines, WINTERSTEIGER also offers various solutions for the supply and removal of cutting material.

The offering ranges from simple roller conveyers and powered roller conveyors in different lengths through to accumulating conveyors in the feeding area. Customer-specific solutions can also be implemented.

Hinged roller conveyors und powered roller conveyors.

The stable support roller for long blocks at the machine's infeed and outfeed points ensure precise cutting results. For this purpose, WINTERSTEIGER has developed sturdy roller conveyors and powered roller conveyors in lengths of 2.5 m, 4 m, and 5.5 m.

The hinged conveyor systems simplify opening of the machine door for rapid tool change.

WINTERSTEIGER also implements customer-specific merry-go-round systems, and with VAP-WINTERSTEIGER's automation expertise, entire production processes can be automated: your requirements lay the foundation for the design!

Feeding magazine – an easy way to boost efficiency.

Inserting multiple wooden blocks into the feeding magazine helps to eliminate interruptions in the workflow and the use of materials. It enables employees to operate multiple machines or run multiple work processes at the same time. It is very easy to set different block heights mechanically.

The feeding magazine and the thin-cutting band saw work together perfectly: combined software controls prevent operating errors and the feeding magazine adapts to the feed speed of the machine.

In order to increase efficiency even further when working with the machine, WINTERSTEIGER also offers an accumulating conveyor magazine. This means that the machine can be operated by only one employee.

Customer-specific complete systems

Within the WINTERSTEIGER Group, VAP-WINTERSTEIGER is the plant engineering and automation specialist. Renowned manufacturers from around the world swear by the "MADE IN AUSTRIA" systems.

Softwood production line for multilayer boards. On this fully automated plant, blocks are thickness-planed, timber is cut into top layers by 3 DSB Twinhead NG XM thin-cutting band saws connected in series, the top layer stack is planed on the sides, lamella are separated and cleaned of dust, and the top layers are quality assessed, all for the production of multilayer boards.

Saw blades developed and produced by Wintersteiger itself.

Customers with exacting requirements require individual tools.

WINTERSTEIGER supplies the best material, optimum saw blade dimensions, and tooth geometries in line with requirements.

Thin-cutting systems and band saws from WINTERSTEIGER are impressive!

- Optimum solution

- Maximum cost-effectiveness

- Reliable partner:

DSB Twinhead Pro XM

Figures. Data. Facts.

| Technical data | Option |

| Main drive | 32 kW |

| Max. cutting width | 310 mm |

| Feed speed, infinitely adjustable (depending on wood type and block dimensions) |

Precision feed: 1 to 18 m/min High-speed feed: 8 – 45 m/min |

| Saw band speed, infinitely adjustable | 20 – 60 m/sec |

| Wet cutting spraying system | For wet cutting as well as for wood types with a high resin or silicate content |

| Saw band tensioning system | Servopneumatic |

| Saw band tracking control (saw band tracking visible via view window) |

Automatic |

| Supply voltage* | 3AC 380-480V 50/60Hz 3AC 575V 60Hz – with transformer 3AC 208V 50/60Hz – with transformer |

More information is available here:

We are here for you!

WINTERSTEIGER's experienced sales staff can help tailor an individual solution to fit your needs!