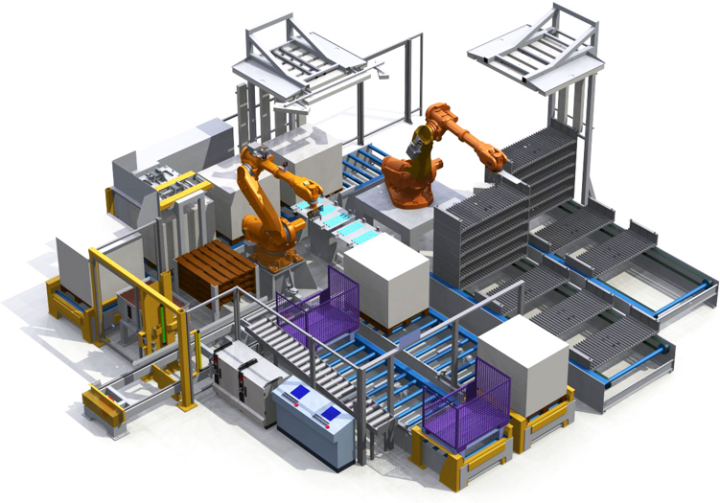

Heat treatment automation for cast parts (Cylinder heads, crankcases etc.)

Our plant satisfies by a extremely robust design, a unique flexibility and short cycle times.

In this plant currently 16 different types of cylinder heads are heat treated at the moment.

- 3D camera technology to determine the type of the casting and its position in space for the pallet-restacking.

- 3D camera technology to determine the casting type and its position in space during restacking the heat treatment racks, after the parts were in the oven.

- DataMatrix reading camera to determine the data matrix codes and thus the overall production data for further processing.

- Database connectivity through our specially designed „VAP-DMC-DATABASE“ Tool.

- Restacking of several shipping containers, pallets, box pallets or heat treatment racks.

- Stacking of several shipping containers, pallets, box pallets or heat treatment racks.

- Graphically guided visualization for easy parameter adjustment.

- Different password levels of special chip that only authorized persons have.

- Transport of the castings, heat treatment racks, pallets, layer pads without lengthy gripper change is possible. The special gripper through our technology, in which you must not change the actual casting gripper.

VAP-WINTERSTEIGER's experienced sales staff can help tailor an individual solution to fit your needs!