Fully automatic part handling for heat-treated castings

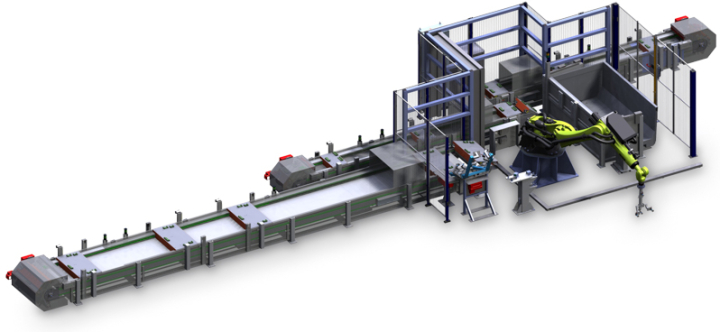

Our plant is part of a large overall system for heat treatment of castings.

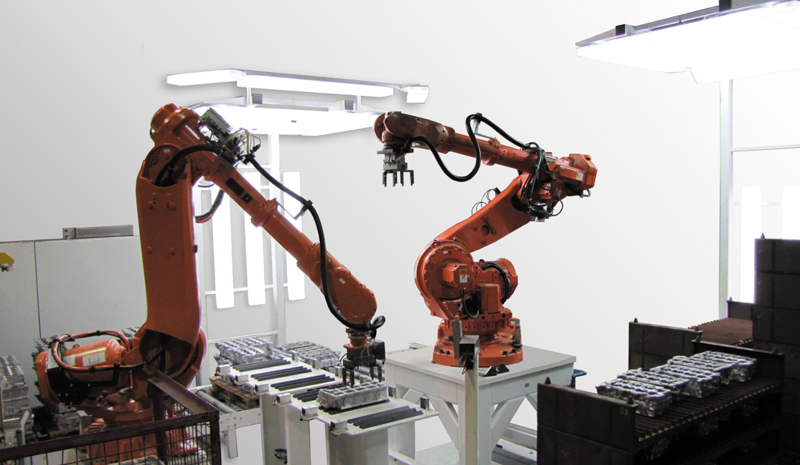

The castings are loaded into charge carriers. These charge carriers are then transported in a homogenizing furnance and remain there in the slow pass, depending on the component type for several hours. After this process, we are required to remove the heat-treated parts of the heat treatment racks, partly to turn 90 degrees and then to provide the parts into the correct pallets circulating conveyor system. Furthermore, the parts need to be labeled. All these tasks are done via a 6-axis industrial robot, which is equipped with various grippers and gripper-change systems.

- Fully automatic unstacking different casting types of heat treatment baskets

- Fully automatic gripper change

- Casting Specific turning device

- Casting labeling (DMC, plain text, numbers)

- Short cycle times through pallet conveyor circulation

- Logistics and automatic supply of the selected workstations

- Solid design, suitable for multi-shift operation

- Ease of use

VAP-WINTERSTEIGER's experienced sales staff can help tailor an individual solution to fit your needs!