Automation & Plants

Decades of expertise in the cutting of high-quality lamellas and sawn veneers have also allowed WINTERSTEIGER to mature into a specialist in upstream and downstream machining processes.

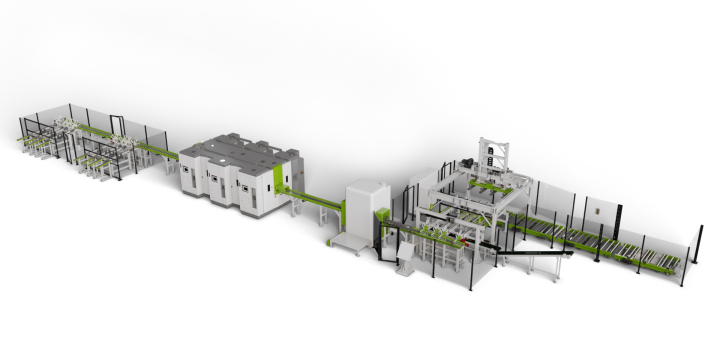

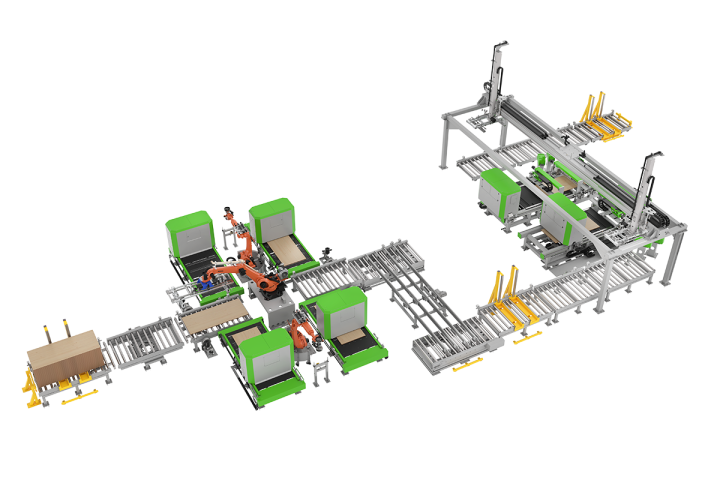

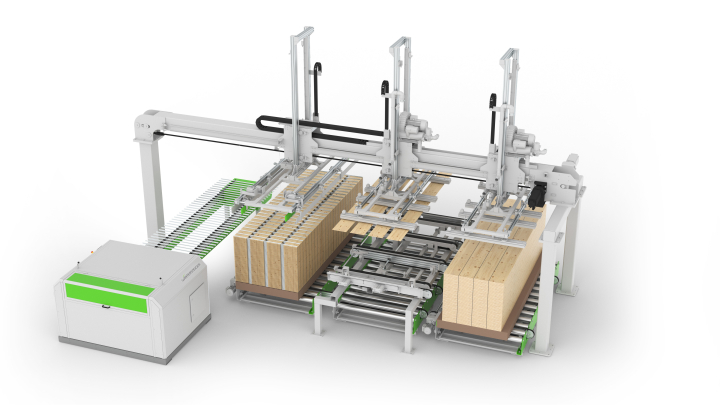

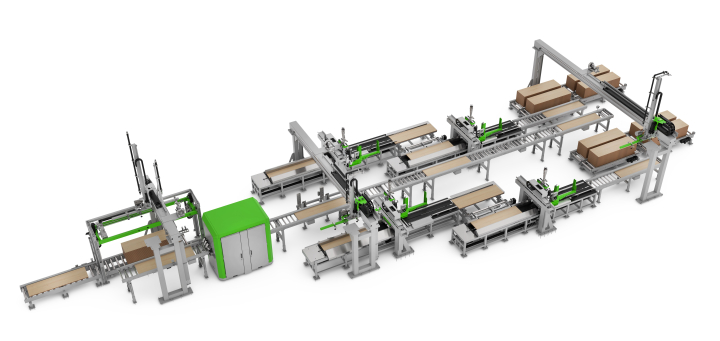

Nowadays, fully automated feeding of a thin-cutting band saw or a thin-cutting frame saw in addition to automated subsequent processing of the cut lamellas is an important part of an efficient overall system.

Here too, WINTERSTEIGER follows the success model of “everything from a single source” with well-thought out solutions. If customer-specific production systems are needed, then the automation expertise of the WINTERSTEIGER group – provided by our plant in Mettmach – is at hand. WINTERSTEIGER and VAP Gruber Automations provide automatic thin-cutting band saw systems and special systems for multi-layer products, as well as automatic timber repair systems for restoring timber surfaces with the TRC (Timber Repair & Cosmetics) product line.

Customer-oriented engineering.

Expansion, modernisation or optimisation of existing systems.