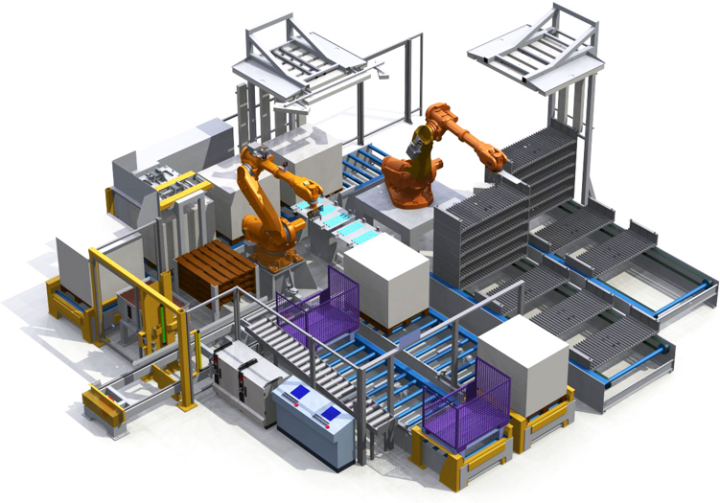

Heat treatment plant for casting parts (cylinder heads, crank cases, etc.)

Our heat treatment plant features extremely robust design, unique flexibility and short cycle times.

Currently, sixteen different types of cylinder heads are undergoing heat treatment.

- 3D camera technique to determine the casting type and its position with space for pallet stacking.

- 3D camera technique to determine the casting type and its position; it should allow space for the heat treatment rack during the unstacking process after the parts were in the oven.

- A data matrix reading camera determines the data matrix code and with it all production data for further processing.

- Database connectivity available with our specially developed "VAP DMC DATABASE" tool.

- Unstacking of different transportation containers, pallets, lattice boxes or heat treatment racks.

- Stacking of different transportation containers, pallets, lattice boxes or heat treatment racks.

- Graphically guided visualisation for easy parameter setting.

- Different password levels available only to authorised persons with a special chip.

- Transport of casting pieces, pallets, intermediate layers without a lengthy gripper change. This is made possible by our special gripper technique in which you do not have to change the actual casting gripper.

VAP-WINTERSTEIGER's experienced sales staff can help tailor an individual solution to fit your needs!