16.04.2018

Two in one: Weitzer Parkett doubles TRC system

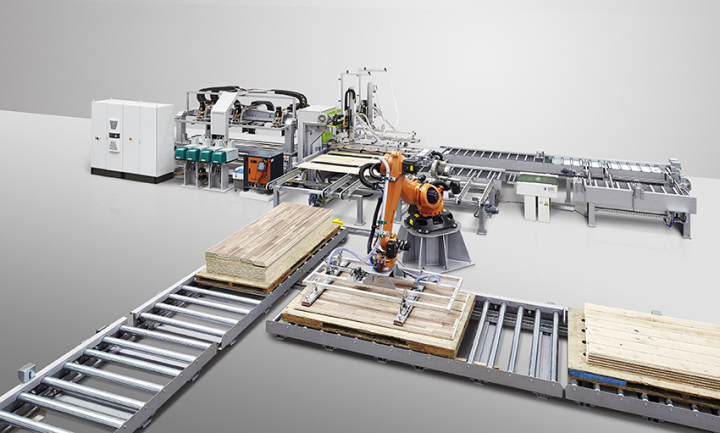

A fully automated TRC 3000 system with a robot

A fully automated TRC 3000 system with a robot

In 2014, Weitzer Parkett – the Austrian market leader in parquet flooring and wooden stairs – decided to switch to automated timber surface repair. The company invested in a fully automated TRC 3000 system with a robot, which was implemented by WINTERSTEIGER and automation expert VAP Gruber (part of the WINTERSTEIGER Group) at the Güssing site.

The 2nd expansion stage.

The rapidly increasing demand for floorboard products – especially in the striking knotted wood ranges – led to the decision to add to the existing TRC 3000 system in 2016. The system is served by a mirrored configuration in the center with the same robot, and Weitzer has been working at twice the original capacity since January 2017. The manual aspect of timber surface repair has therefore been reduced and the efficiency of the manufacturing process increased.

SHARE:

Technical director Martin Karner

Technical director Martin Karner

Technical director Martin Karner is extremely pleased with the system and confirms its strengths: “We have improved the quality of our products as a result, which means that we don't have to rework as many imperfections. The system's availability is very good.”

Weitzer Parkett has seen an additional quality benefit in that the filler material is injected by the TRC system at high pressure, resulting in better adherence than during manual improvement works. 24 million injections – this impressive total reflects the high performance level of the system, which has processed around 750,000 m² of wood over the last 12 months.

A family enterprise with high ecological standards.

Founded in 1831, Weitzer Parkett employs more than 600 members of staff and produces roughly 2.6 million m2 of parquet flooring every year. The family business in its 7th generation of ownership is present in more than 30 countries. Weitzer Parkett has production facilities at its headquarters in Weiz (Styria) and in Güssing (Burgenland). The company takes responsibility for the environment and strives for the sustainable use of wood as a resource: Weitzer Parkett does not process any tropical timber and all its products bear the Blue Angel ecolabel. All wood by-products are converted into district heating and green electricity – the company's own biomass heating plant supplies roughly 1,700 households with electricity and heating.