04.03.2024

TRC Woodpatch: New repair technology for wooden boards

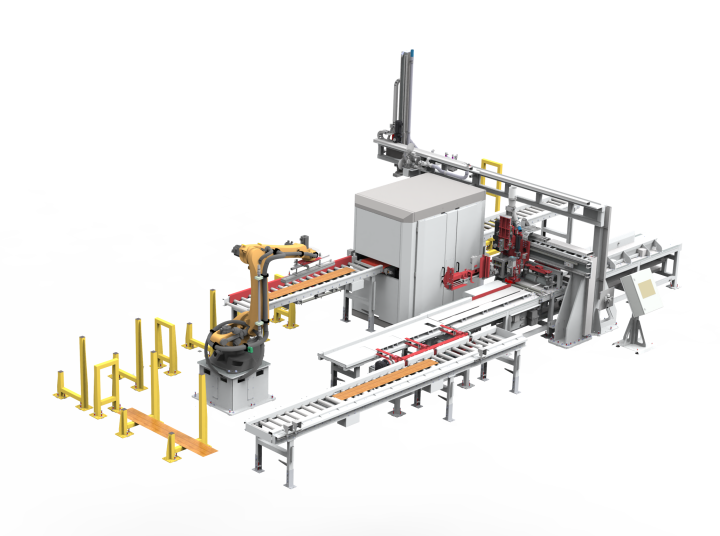

With the new TRC Woodpatch, VAP-WINTERSTEIGER is offering a system for the fully automated repair of wooden boards using wood patches. It is particularly effective on multilayer boards such as formwork panels, glulam panels, and solid wood boards.

Patching is a completely new technology that VAP-WINTERSTEIGER has introduced with this product, whereby the filling material is produced from the customer's own wooden strips during the repair process. These 'patches' are then inserted precisely in the direction of the grain. A huge advantage of the TRC Woodpatch is that it repairs boards on both sides in just one pass, as the system automatically turns the board once the front is repaired and then processes the back.

Maximum precision thanks to "Faulty Spot Eye"

The proven VAP-WINTERSTEIGER "Faulty Spot Eye" scanning technology is also used in the TRC Woodpatch. This identifies different types of defect and determines their position with a high degree of accuracy and efficiency, in order to then position the wood patches precisely. The Faulty Spot Eye also detects discoloration, which can be taken into account when assessing the different quality levels.

Flexibility thanks to a modular design

If capacity needs to be increased, multiple repair lines can be added to the TRC Woodpatch. Customers can also add further options to the TRC Woodpatch, such as automatic refilling of the wooden strips in the magazine, to customize it and tailor it to their production requirements and workflows.

SHARE: