TRC Woodpatch,

fully automated wood patching system

TRC Woodpatch, fully automated wood patching system

Repair of panels.

TRC Woodpatch, fully automated wood patching system

Repair of panels.

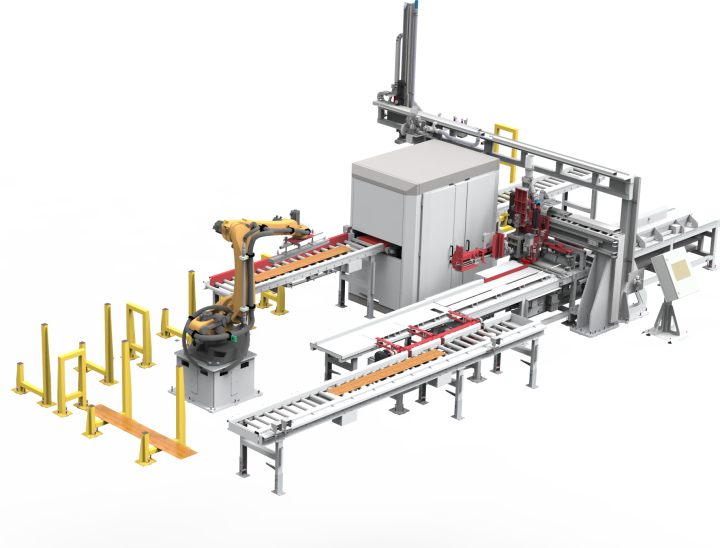

The TRC Woodpatch is the perfect solution for the automatic repair of wooden boards with wood patches. It has been specially developed for multilayer boards (e.g., formwork panels, glulam panels, solid wood boards, etc.).

The fully automated TRC Woodpatch timber repair system for multilayer boards (for example, formwork panels), glulam panels, solid wood boards, etc., scans the board on both sides with Faulty Spot Eye (FSE) and detects the defect. The defect is then milled out and repaired.

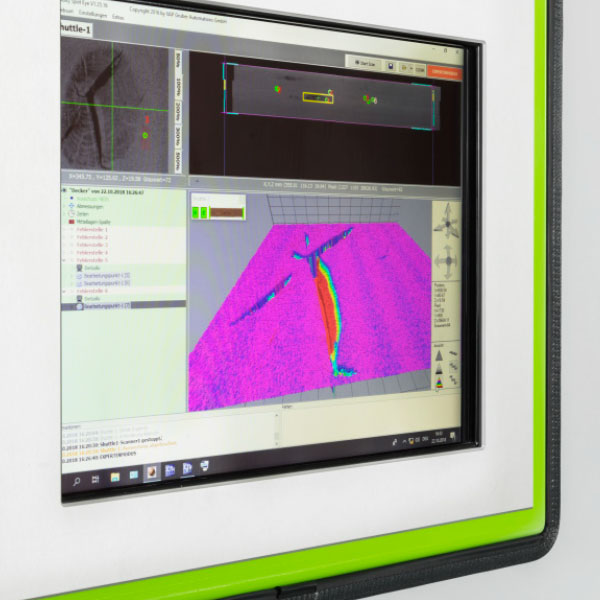

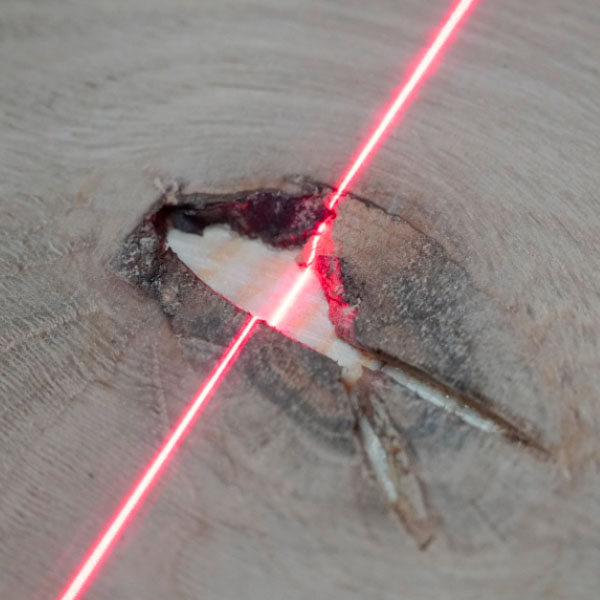

This technology enables various types of defects to be detected and analyzed and their positions to be determined. What is more, the Faulty Spot Eye (FSE) allows discoloration to be detected and taken into account when evaluating the different quality levels.

Straight after the repair of the first side of the board, it is possible to turn the board and repair the second side in another pass. The board can also be repaired on both sides in just one pass using two TRC Woodpatch systems connected in series.

Your benefits summed up:

- The optional panel destack aid helps to efficiently destack glued boards

- The flexible scanning system detects and analyzes every defect on both sides of the board in just one pass

- Produce patches from your own wooden strips – buying in extra wood is a thing of the past

- Repairs performed on both sides on a single line for maximum efficiency

- Perfect results: Patches are inserted precisely in the direction of the grain

- Modular design: Expandable lines for increasing capacity requirements

Faulty Spot Eye

Using the tried-and-tested "Faulty Spot Eye" scanning technology, the innovative system detects and analyzes defects on both sides of the board and repairs them highly efficiently and precisely. The scanning technology identifies different types of defects and determines their position with a high degree of accuracy, in order to then position the wood patches precisely. The Faulty Spot Eye also detects discoloration, which is taken into account when assessing the different quality levels.

Just one repair pass required per board

Another major advantage: The TRC Woodpatch repairs both sides of the board in a single pass. Once the first side has been repaired, the board is automatically turned over and machined again with another unit. Thanks to its modular design, the system can be flexibly expanded at a later date to increase productivity.

In addition to its flexibility and unbeatable precision, the TRC Woodpatch offers a very high magazine capacity, whereby the large number of wooden strips in the magazine allows the machine to optimize the repair process and keeps downtimes to a minimum.

WINTERSTEIGER offers the option of automatically refilling the wooden strips, which further reduces the work involved in operating the system. Producing the wood patches from your own wooden strips significantly reduces the costs of the repair process.

The repair process explained step-by-step

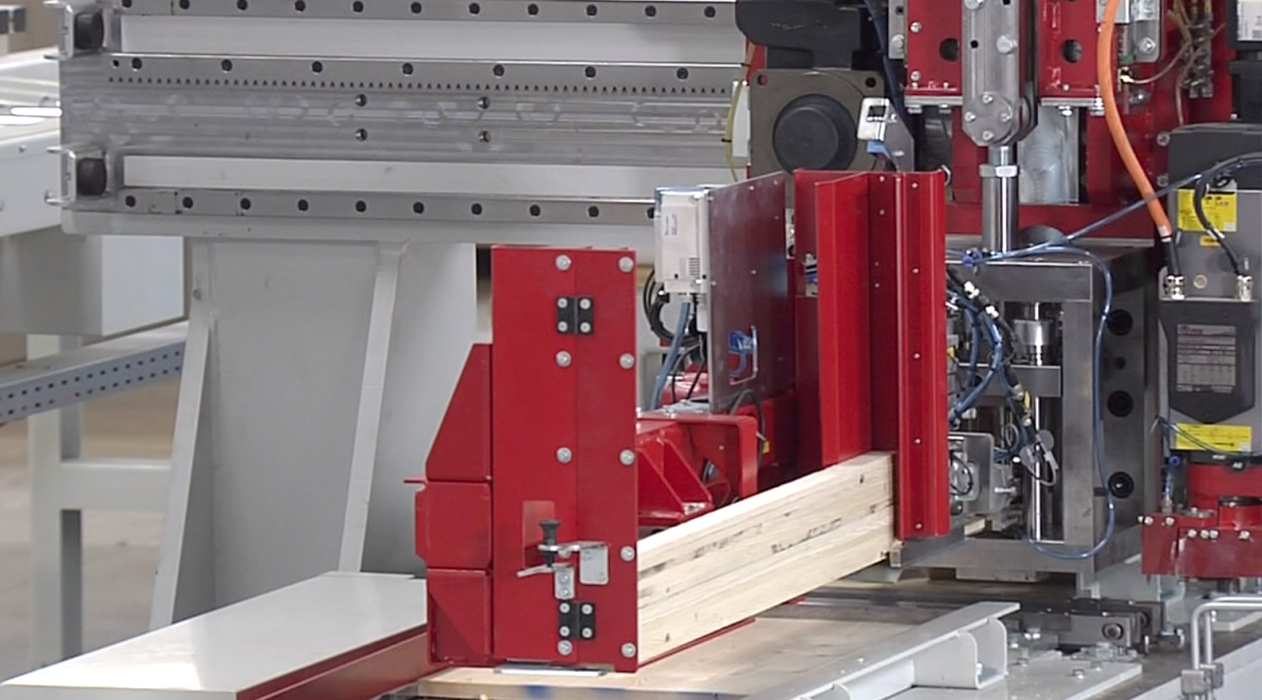

The Woodpatch repair process is simple and efficient: The motor spindle drills out the defect while the patch is created from the wooden strip. The patching unit moves from the drilling position to the setting position and the punch presses the patch (plug) into the drilled-out defect. The gripper pushes the wooden strip onwards to produce the next patch.

The TRC Woodpatch optimizes the wood repair process and – thanks to the modular design – the system can be flexibly expanded with multiple repair lines to achieve even greater productivity.

Application areas:

- Multilayer boards (e.g., formwork panels)

- Glulam panels

- Solid wood flooring

- And much more

Wood dimensions:

- Length min. / max.: 1500 mm / 3000 mm

- Width min. / max.: 500 mm / 510 mm

- Thickness min./max.: 10 mm / 20 mm

WINTERSTEIGER’s experienced sales staff can help tailor an individual solution to fit your needs!