TRC Board,

fully-automatic wood surface repair

TRC Board, fully-automatic wood surface repair

Repair of single boards.

TRC Board, fully-automatic wood surface repair

Repair of single boards.

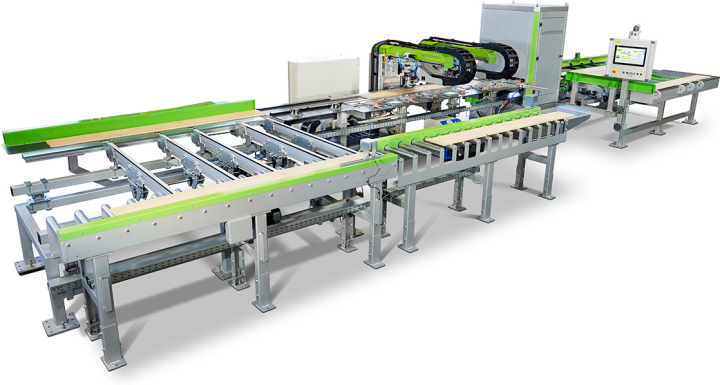

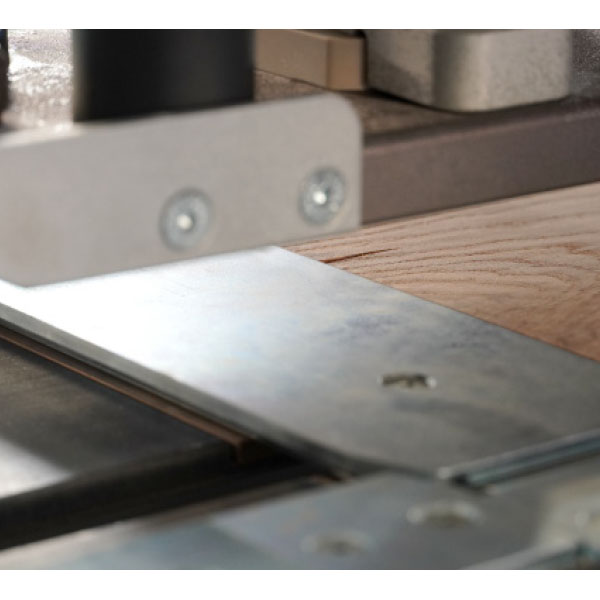

TRC Board is a modular platform for the fully automatic repair of individual boards.

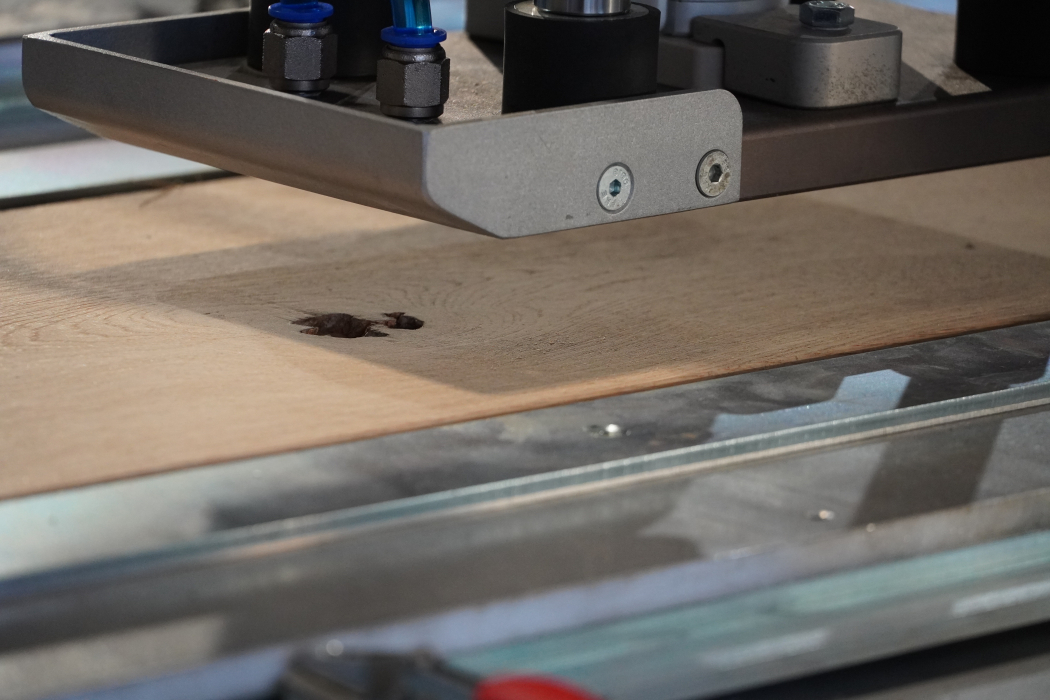

This system is intended for medium output with high performance for commercial and industrial enterprises. It produces perfect repairs of damaged timber surfaces. Defects are repaired with thermoplastic or organic filling material using injection units. No filling material is wasted thanks to the precise calculation of the filling quantity and precision injection.

The TRC Board is also optionally equipped with a face ruler, which can also be used to measure and repair cracks on the face of the material. In addition to this, all defects directly around the edges can also be filled.

Duplex version.

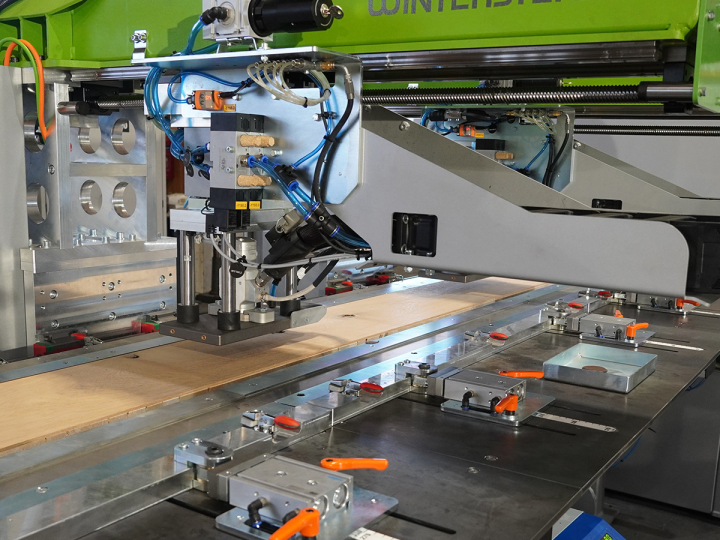

The system can be optionally equipped with 2 different filling materials at the same time. Each of the 2 repair units is equipped with an additional injection unit.

Cooled supporting table.

Thanks to the cooled, full-length supporting table with external cooling system, products with rough defects, such as knotholes through the entire lamella thickness as well as lamella/top layers, can be repaired with ease.

Handling system – manual feeding.

The feed is designed so that the boards can be placed close to one another. This also enables (automated) layer-by-layer placement of boards on the cross conveyor.

Handling system – manual removal.

The TRC Board can be optionally equipped with a return conveyor system, which can be operated by just one person. The return conveyor system consists of a cross conveyor and a roller conveyor. The roller conveyor is connected to the cross conveyor and conveys the boards back so they can subsequently be stacked manually.

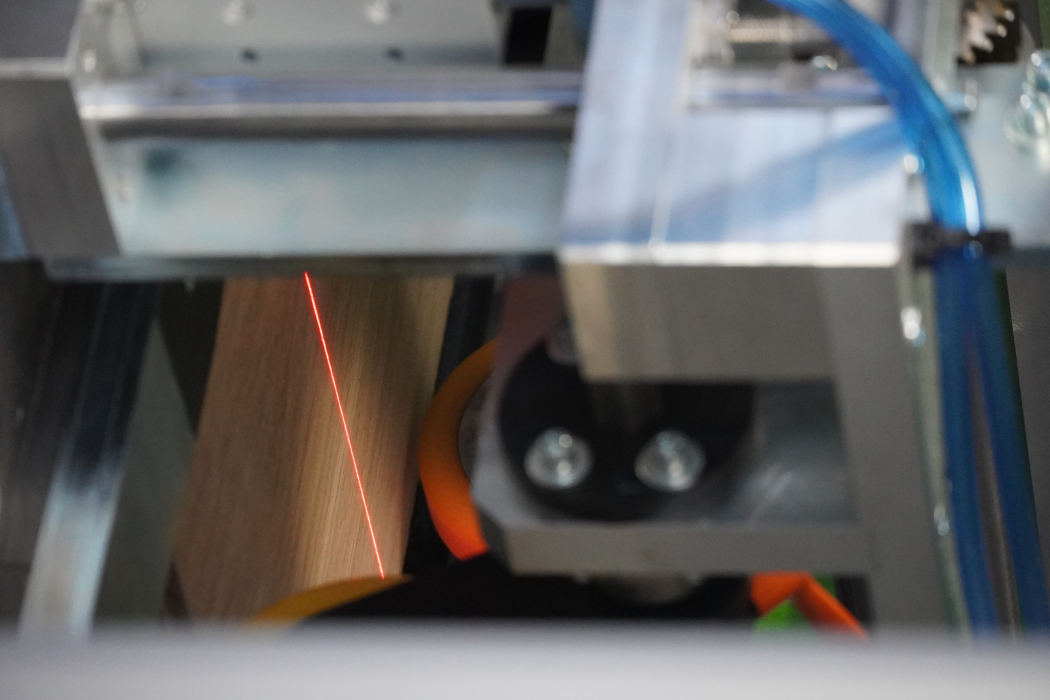

Control scan.

If required, a second scan unit can be integrated. It controls the quality of the boards following repair.

Random length.

The „Random Length“ function allows boards of different lengths to be processed directly one after another without the need for any adjustment. This function comes as standard with TRC Board.

Face ruler and side guide.

The face ruler and side guide are needed when the damage is on the edge of the boards. The following profile seals are available:

- Longitudinal profile seals (right and left)

- Front/end profile seals

Handling system – manual removal.

The TRC Board can be optionally equipped with a return conveyor system, which can be operated by just one person. The return conveyor system consists of a cross conveyor and a roller conveyor. The roller conveyor is connected to the cross conveyor and conveys the boards back so they can subsequently be stacked manually.

Control scan.

If required, a second scan unit can be integrated. It controls the quality of the boards following repair.

Random length.

The „Random Length“ function allows boards of different lengths to be processed directly one after another without the need for any adjustment. This function comes as standard with TRC Board.

Application areas:

- Top layers

- Engineered wood flooring

- Solid wood flooring

- Finished lumber

- etc.

Wood dimensions:

- Min. / max. length: 500 mm / 3000 mm

- Min. / max. width: 100 mm / 350 mm

- Min. / max. thickness:

3 mm / 30 mm (TH version),

9 mm / 30 mm (OR version)

Options:

In order for us to supply you with the perfect system for your capacity, repair, material flow, and other requirements, we make use of a modular system with the following options and/or configurations:

| Number of repair units | 1 to 3 injection units |

| Filling material |

|

| Options for TH version |

|

| Handling system |

|

| Process flow | Control scan |

Reference systems

TRC Board 2TH

| Filling material | Thermoplastic (TH) 2 injection units |

| Handling system | Manual feeding of the cross and return conveyor |

| Options |

Side guide and face ruler Cooled supporting table |

| Process flow | No control scan |

| Application | Engineered wood flooring industry |

| Board size | W: 100 mm – 350 mm L: 920 mm – 2000 mm |

WINTERSTEIGER’s experienced sales staff can help tailor an individual solution to fit your needs!