01-19-2026

Precision and efficiency for premium solid wood solutions

Harald Bleckenwegner (Area Sales Manager, WINTERSTEIGER) with Mr. János Pfiffer (CEO) in front of the thin-cutting band saw

Harald Bleckenwegner (Area Sales Manager, WINTERSTEIGER) with Mr. János Pfiffer (CEO) in front of the thin-cutting band saw

Pfiffer Bútor enhances quality and output with the WINTERSTEIGER DSB Singlehead NG XM

Pfiffer Bútor Mór Kft. is a family-owned company with more than 30 years of experience in solid wood processing. Based in Mór, Hungary, the company produces premium solid wood furniture, furniture fronts and interior architectural elements for joineries and project-oriented customers – always with a strong focus on quality, dimensional accuracy and delivery reliability.

With growing demand for multi-layer solid wood components – particularly the company’s self-developed 3-layer door constructions – the requirements placed on production processes increased significantly. The key challenge was to maintain exceptional quality and on-time delivery while producing lamellae with precise thickness, high repeat accuracy and minimal distortion – especially critical for multi-layer components and furniture fronts.

SHARE:

Thin-Cut Technology as the Key Enabler

Thin-Cut Technology as the Key Enabler

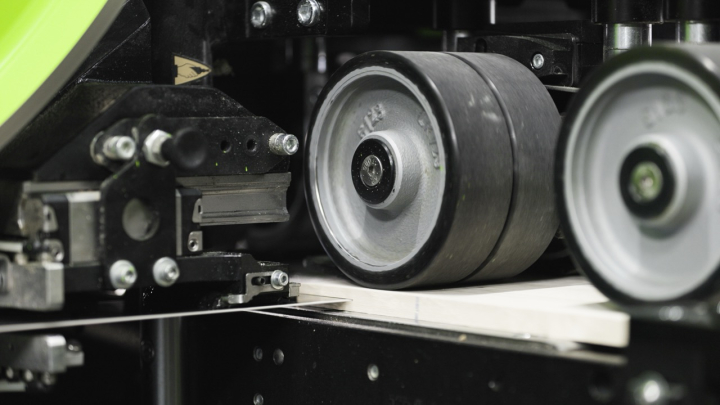

As part of a successful investment project supported by public funding, Pfiffer Bútor decided to install the WINTERSTEIGER DSB Singlehead NG XM thin-cut band resaw. The machine was commissioned in the first half of 2025 and seamlessly integrated into the solid wood processing area of the production facility, specifically for manufacturing lamellae used in 3-layer door elements.

The decision was driven by several decisive factors:

- Extremely thin kerf width for maximum material yield

- Outstanding dimensional accuracy and repeatability

- Energy efficiency and fast set-up times

- High machine reliability, combined with excellent service support, availability and flexibility from WINTERSTEIGER – clearly outperforming alternative solutions on the market

Higher Yield, Consistent Quality and Improved Process Stability

The Fortuna door series is characterized by its clear, modern design.

The Fortuna door series is characterized by its clear, modern design.

Following installation, production workflows were optimized so that the DSB Singlehead NG XM now performs the precise separation of solid wood blocks into lamellae. The extremely thin saw band reduces material loss while delivering higher accuracy and superior surface quality.

A major efficiency gain comes from the ability to process blocks with a cutting width of up to 350 mm. This allows Pfiffer Bútor to work with wider blocks, reducing the number of processing steps and significantly increasing throughput. The result is a 10–30% increase in lamella output from the same volume of raw material, along with faster, more predictable and resource-efficient production.

Stronger Structures, Higher Aesthetic Value

The improved dimensional accuracy, repeatability and surface quality directly enhance the structural stability and visual appearance of Pfiffer Bútor’s 3-layer doors – a decisive factor for high-end furniture and interior design projects. With the DSB Singlehead NG XM, Pfiffer Bútor demonstrates how WINTERSTEIGER’s thin-cut technology enables premium wood processors to combine outstanding quality, material efficiency and long-term competitiveness.