DSG Notum Pro

Thin-cutting frame saw

DSG Notum Pro Thin-cutting frame saw

Thin-cutting frame saw.

DSG Notum Pro Thin-cutting frame saw

Thin-cutting frame saw.

With the DSG Notum, WINTERSTEIGER has crafted the perfect synthesis of decades of experience and state-of-the-art technology. Our aim is to deliver the best technology at the best prices and provide cost-effective access to the premium segment in the process.

The DSG Notum showcases its strengths in day-to-day use with its characteristic reliability and efficiency.

For example, it can be used to produce high-quality lamellas (sawn veneer) for:

- Engineered wood flooring

- Multilayer boards

- Doors

- Windows

- Furniture

- Pencil slats

- Musical instruments

- and much more.

Your benefits summed up

Notum – the experience

- From the inventor of the thin-cutting frame saw

- Precision and performance for all requirements

- Expertise and know-how in use all around the world

Proven & innovative

- Electronically controlled precision feed

- Centric saw frame tensioning

- 266 mm cutting height

- Advanced frame guide system

- Optimized air-jet system

User-friendly operation

- Optimum accessibility thanks to modular machine design

- Electrically adjustable down pressure system

- Easy operation via touch screen display

- Central control cockpit

Notum – the experience

From the inventor of the thin-cutting frame saw

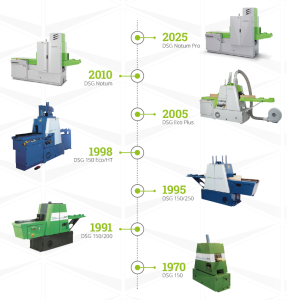

The DSG Notum Pro continues WINTERSTEIGER’s tradition of combining the highest quality with resource-saving processing. It is a tradition that began with the predecessor model DSG 150 in 1970 and has since established itself worldwide. In the DSG Notum Pro, WINTERSTEIGER has now introduced the next family of frame saws, and the global technology leader has poured all of its experience into developing this new product. With high precision, minimal kerf, and ready-to-glue surface quality, WINTERSTEIGER has long been a leader in thin-cutting frame saws. The comprehensive portfolio of machinery and tools developed and produced by WINTERSTEIGER plus service guarantees the long-term performance of every single machine.

The best technology at the best price for cost-effective access to the premium segment.

Expertise and know-how in use all around the world

Expertise and know-how in use all around the world

There are currently more than 2,000 WINTERSTEIGER thin-cutting frame saws in use all over the world. Every single one of these machines is testament to WINTERSTEIGER’s expertise and know-how. The DSG Notum Pro is proving to be the latest chapter in the success story that WINTERSTEIGER and its customers continue to write together.

How do you exceed high expectations?

By offering benefits as standard

Every investment requires careful consideration, and economic criteria are the deciding factor. Even the basic version of the DSG Notum comes with an impressive variety of standard product features, guaranteeing a high level of satisfaction and consistent performance.

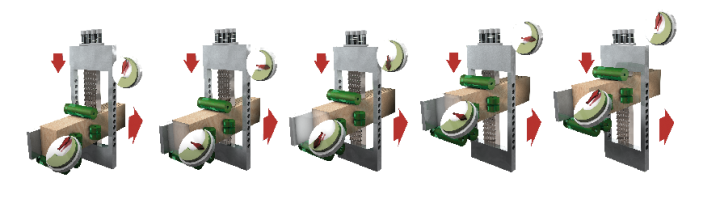

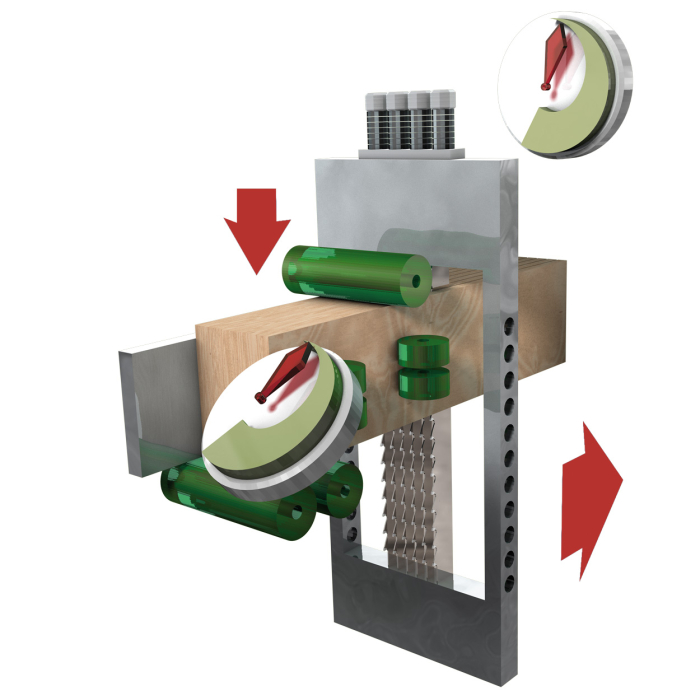

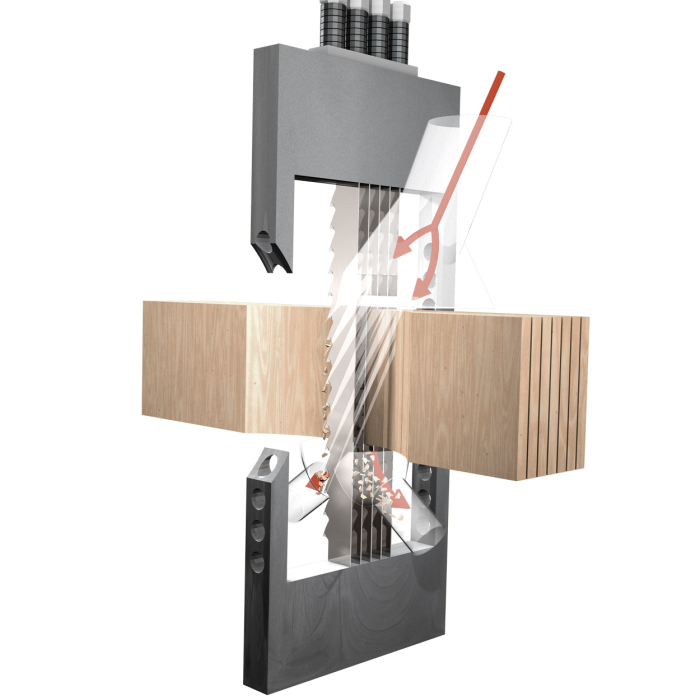

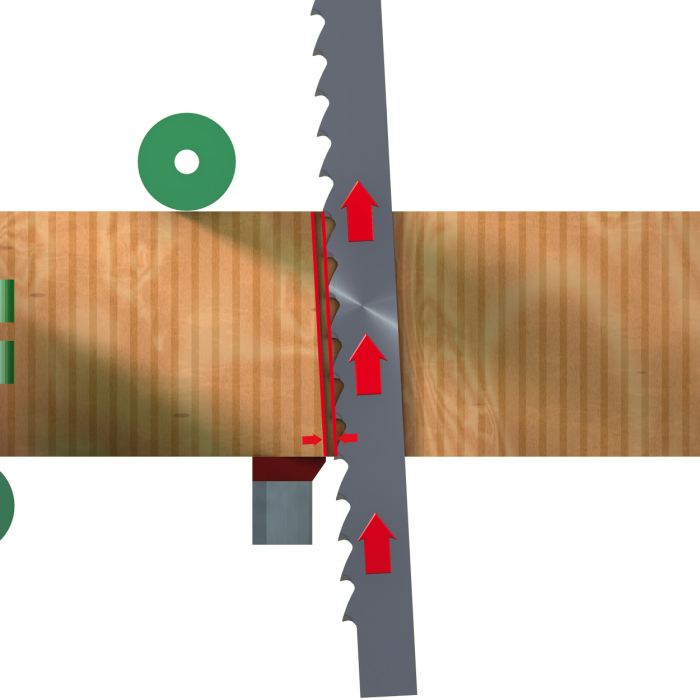

Electronically controlled precision feed.

An electronically controlled precision feed at the charging and discharging unit of the machine drives the transport rollers. This ensures each saw tooth removes material with precision – at every stage of the saw frame movement. The result is a long saw blade service life and smooth surfaces with extremely high accuracy.

Product features at a glance

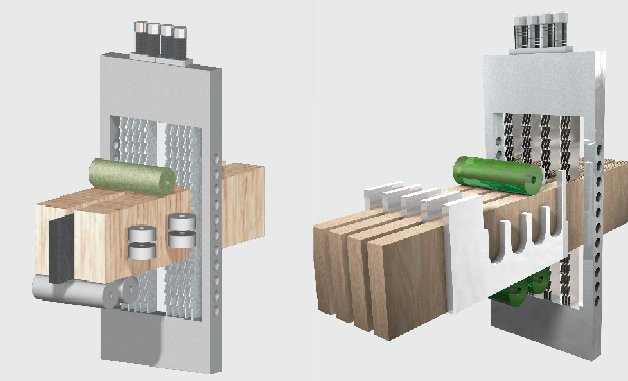

Magazine

The magazine ensures continuous feeding of the wooden blocks. Multiple machines can be operated by just one person.

Electronically controlled precision feed

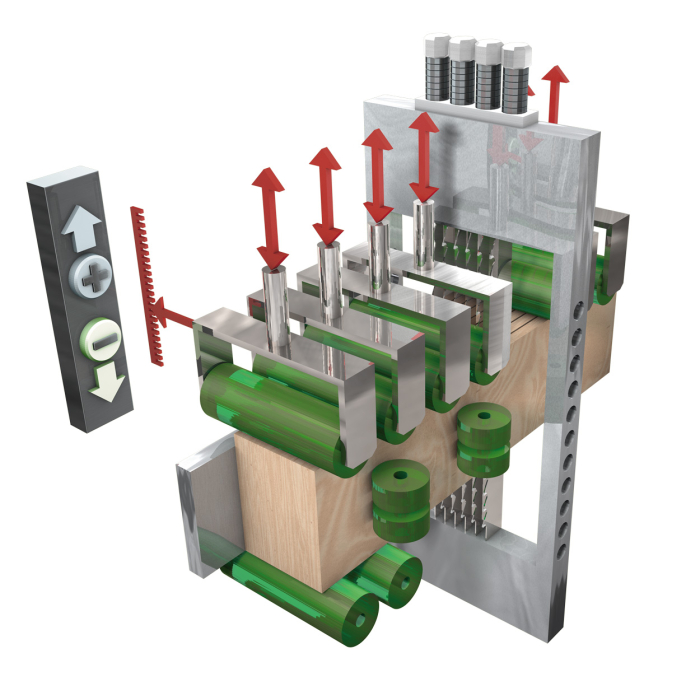

Down pressure system

The electrically adjustable down pressure system can adjust the block height automatically and minimizes adjustment times.

Center guide

Side guide

Channel system

Splinter guard

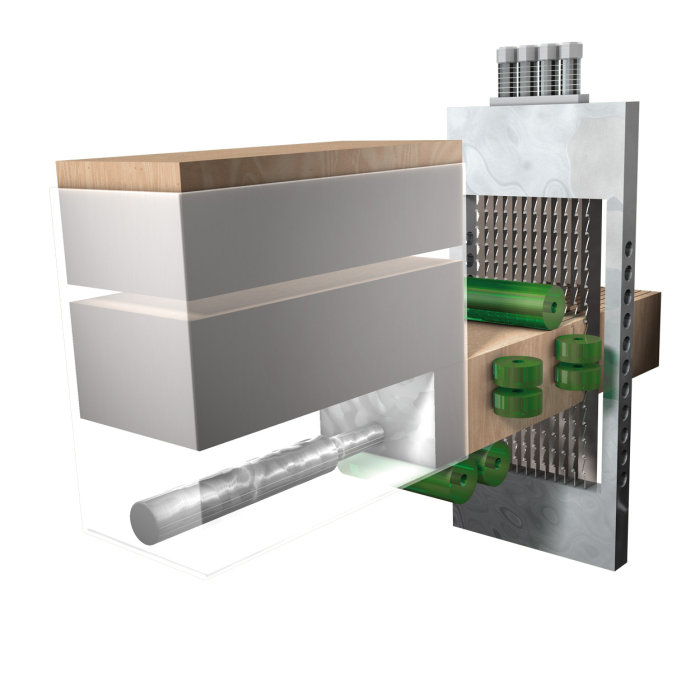

The built-in splinter guard guarantees optimum stabilization of the underside of the block when the saws emerge.

Air jet

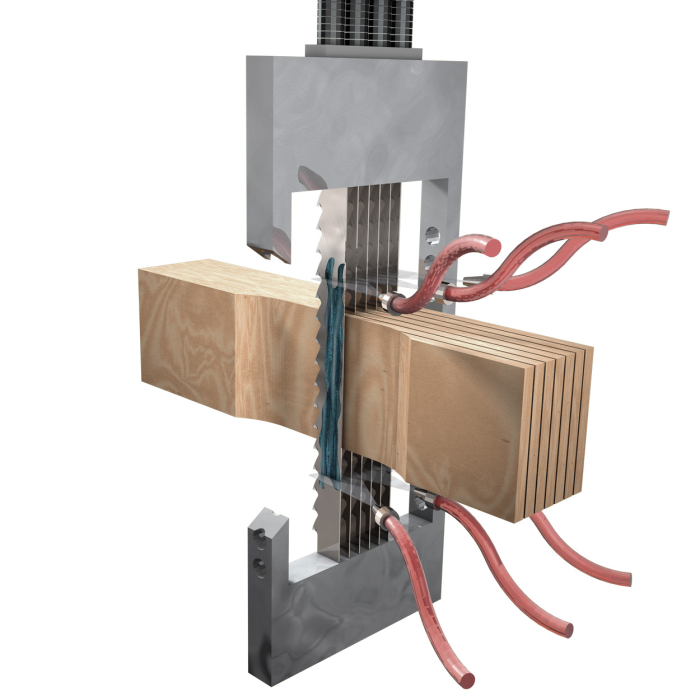

The air jet supplies a continuous flow of air directly into the cutting area of the saw tooth, clearing the cutting area of sawdust during the cutting process. This keeps friction to a minimum and protects the saw teeth against blunting, thereby ensuring that the saws do not heat up. User benefits: The saw boasts a longer service life, produces a largely dust-free lamella, and can be used for cutting difficult-to-machine wood types.

Spraying system

Spraying a biological anti-stick agent onto the saw blade prevents resinous sawdust from sticking to the saw blade. The spraying intervals can be set individually according to the wood type and customer requirements.

Wet cutting system

In addition to the air jet and spraying system, compressed air can also be used to remove dense, fresh sawdust from the bottom end of the saw.

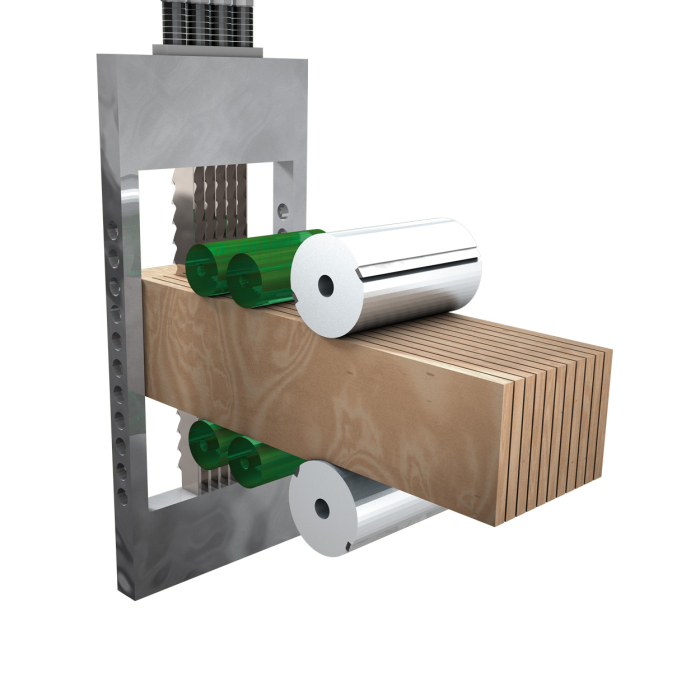

Double planer

The newly developed double planer boasts optimal accessibility, with all components being mounted on one side; it also features a compact design, and easy tool change.

User benefits: Precision joining edge for gluing, no transport marks on the face of the lamellas, perfectly parallel lamellas.

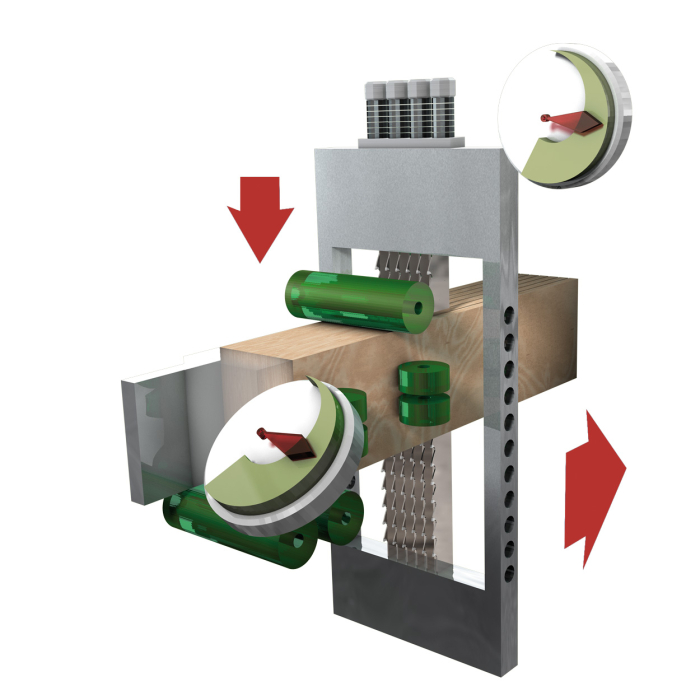

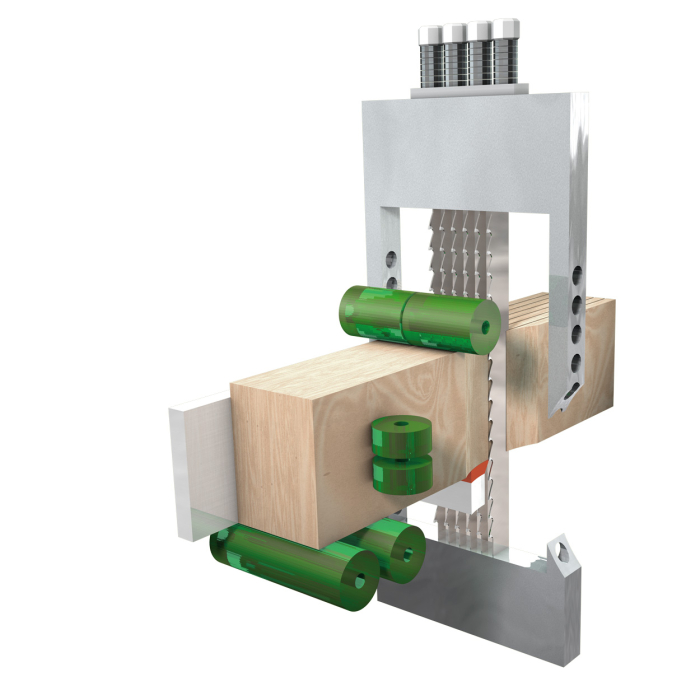

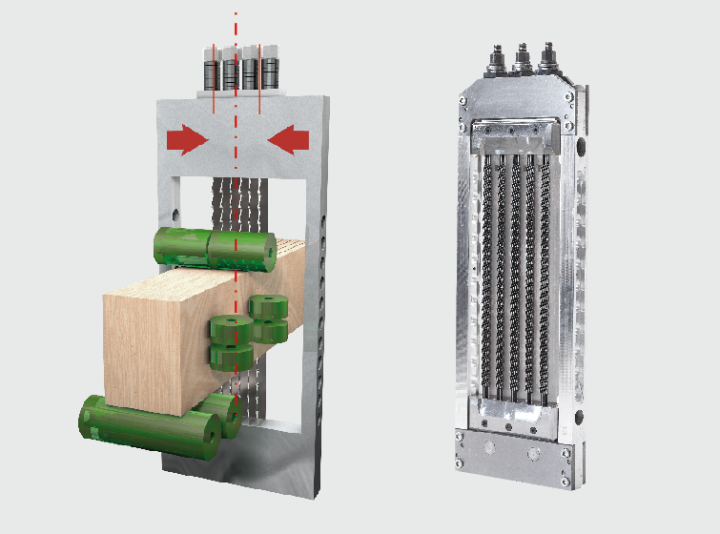

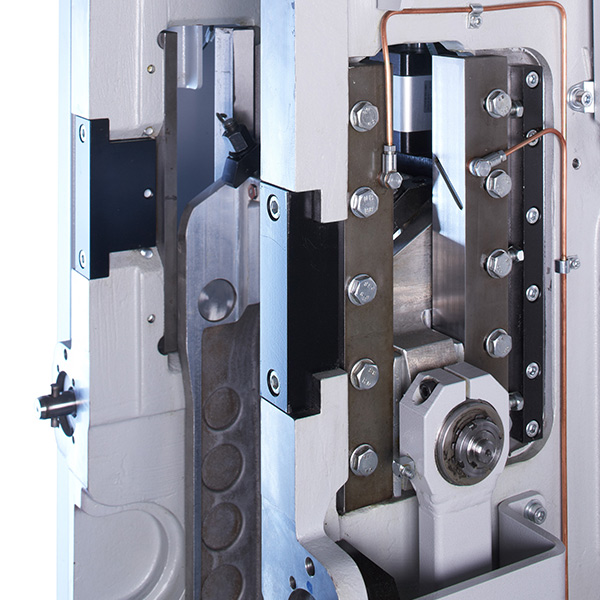

Centric saw frame tensioning

Centric saw frame tensioning

The saw frame’s symmetrical design guarantees uniform saw blade tension throughout. This improves the cutting accuracy and increases the service life of the thin-cutting saw blades. The individual saws can be replaced quickly and ergonomically.

Highlights

Consistent clean cutting

The feed and stroke movements interact perfectly with the saw overhang to enable consistent clean cutting as the saws move upwards. The result is optimal cutting performance in combination with the WINTERSTEIGER air jet system.

266 mm cutting height

WINTERSTEIGER’s consistent focus on customer requirements is also underlined by the standardized cutting height of 266 mm. This means that, even in the basic version, lamellas for the production of extra-wide planks, door elements, and panels can be cut with familiar WINTERSTEIGER precision and a kerf from 1.1 mm.

Advanced frame guide system

The tried-and-tested frame guide principle with free-sliding guides has now been perfected with the redesign of the key component that transfers the stroke movement. The frame guide has been structurally reinforced and redesigned to be more maintenance-friendly, thereby increasing the availability of the machine while at the same time meeting more exacting cutting height requirements.

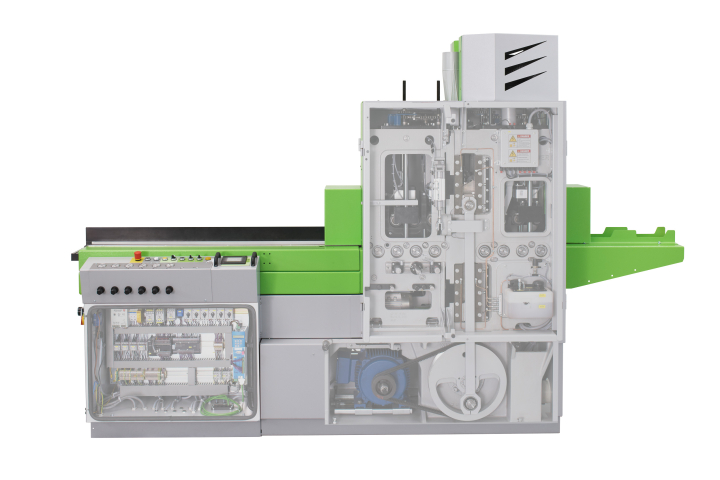

Optimum accessibility

The innovative design ensures easy access to all machine components. For example, the saw frame can be replaced ergonomically while the machine is open. What’s more, machine availability has also been increased as minimal time is required for adjustment work, setup times, and maintenance.

Tolerance-free linear guides also ensure precise travel. The sturdy locking mechanism guarantees the machine remains stable at all times.

Easy to operate

The compact and easy-to-read touchscreen display allows the operator to set values, switch menus, and view maintenance instructions and data.

Central control cockpit

All control elements are operated via the centrally positioned touchscreen display, control switches, and pressure governor. This means that mechanical adjustments are no longer required. The control cockpit is vibration-decoupled. This protects all pneumatic and electronic components from vibrations. This is beneficial as it increases the service life and availability of all control elements.

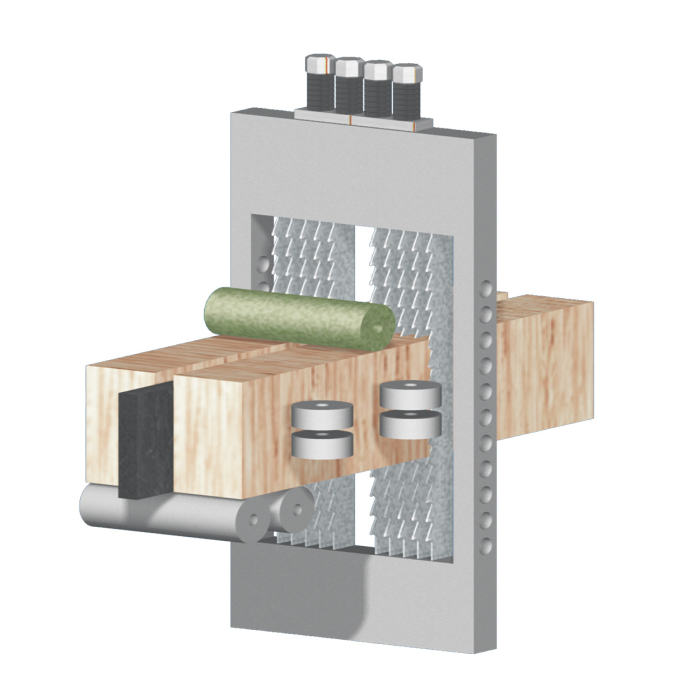

Individual block guide system

Demanding requirements require tailored solutions.

That’s why WINTERSTEIGER offers individually tailored block guide systems:

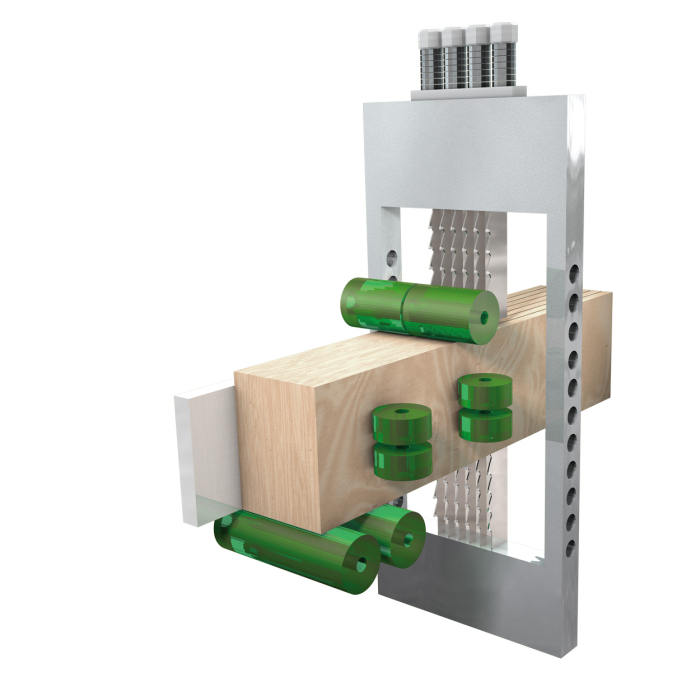

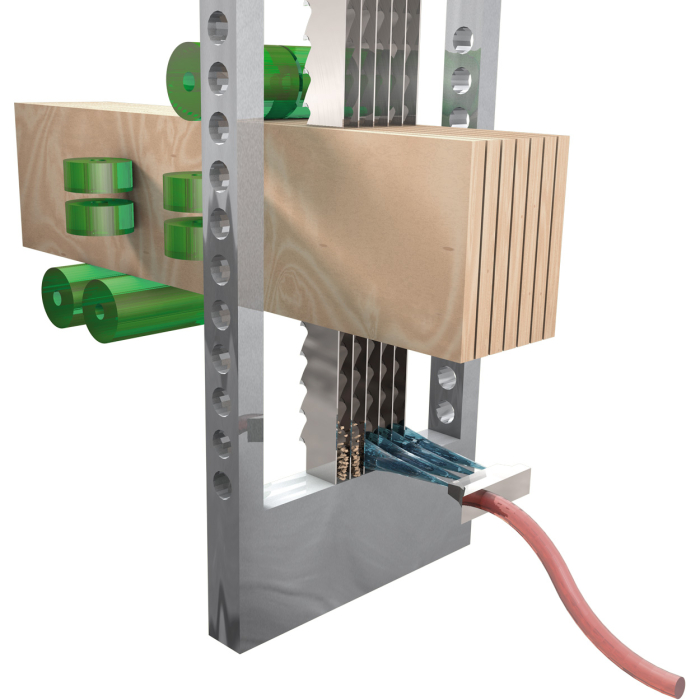

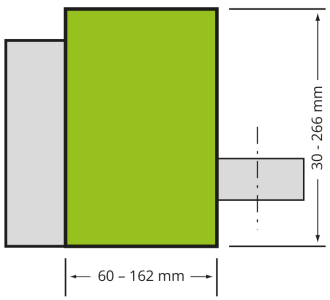

Side and center guide

In the side guide position, the wooden block is guided along the gage positioned at the side by pneumatically controlled pressure rollers.

Block width: 0–162 mm

Block height: 30–266 mm

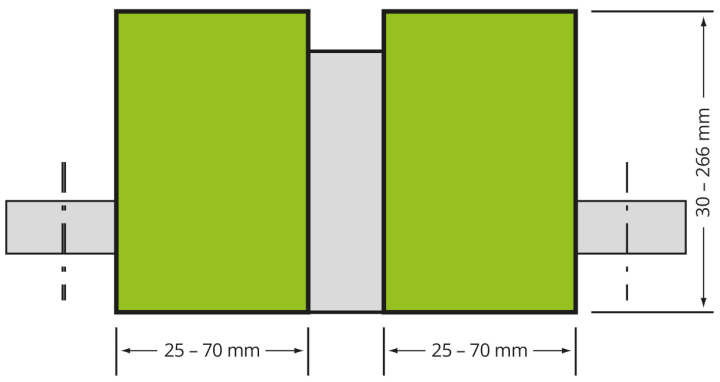

Center guide

In the center guide position, two wooden blocks are guided along the left and right sides of the centrally positioned gage by pneumatically controlled pressure rollers.

Block width: 2 x 25–70 mm

Block height: 30–266 mm

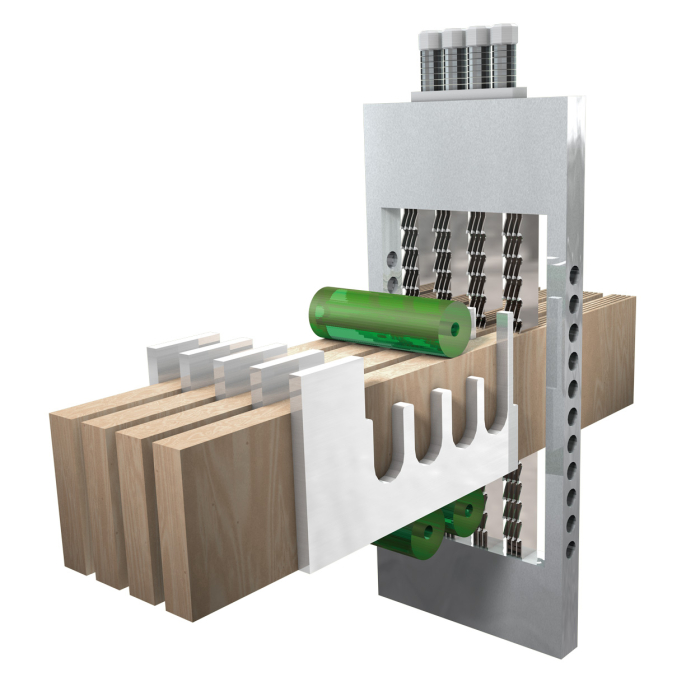

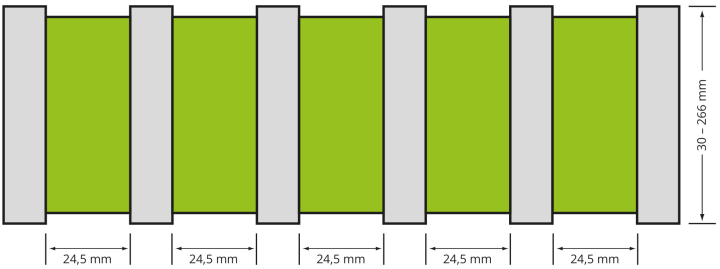

Channel system

The easy-to-upgrade system processes multiple blocks at the same time.

Channel design: According to customer requirements

Number of channels: 2–5 channels

Block height: 30–266 mm

Block jams are avoided thanks to the conical block inlet (even pre-planed material can be problematic.)

Specially machined guide rails ensure that the blocks are precisely aligned immediately before they are cut

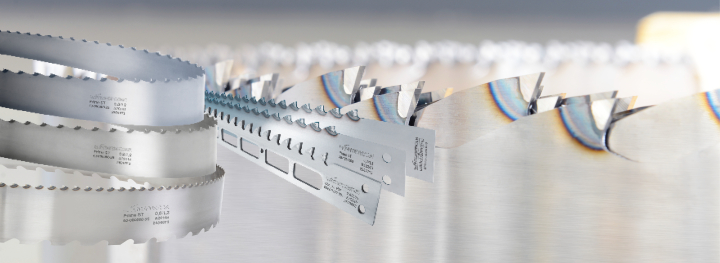

Saw blades developed and produced by Wintersteiger itself.

Customers with exacting requirements require individual tools.

WINTERSTEIGER supplies the best material, optimum saw blade dimensions, and tooth geometries in line with requirements.

Thin-cutting systems and band saws from WINTERSTEIGER are impressive!

- Optimum solution

- Maximum cost-effectiveness

- Reliable partner:

WINTERSTEIGER after-sales service.

When the delivery ends the support begins.

WINTERSTEIGER after-sales service.

When the delivery ends the support begins.

The best time to evaluate the quality of an investment is several years after delivery. For this reason, WINTERSTEIGER has an after-sales service that is available to you all over the world.

- Commissioning and training

- Production support

- Proactive maintenance

- Blanket orders for consumables and saws

- On-call help desk.

WINTERSTEIGER’s experienced sales staff can help tailor an individual solution to fit your needs!