10-13-2021

Digital, powerful, high precision: The new DSB Twinhead Pro XM thin-cutting band saw

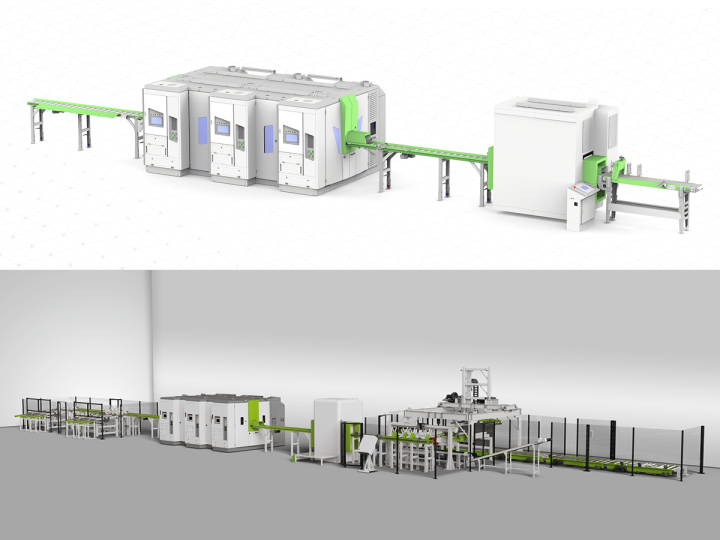

Basic version with two saw modules

Basic version with two saw modules

WINTERSTEIGER AG from Upper Austria has made the powerful DSB Twinhead thin-cutting band saw fit for the future: with its digital solutions and a completely overhauled user interface, the new DSB Twinhead Pro XM heralds the start of the next generation of machines. The band saw has also been optimized for the softwood segment.

The new DSB Twinhead Pro XM with two saw modules is a thin-cutting band saw machine for industrial use where a large capacity is required. The proven predecessor model has been optimized from various viewpoints. Andreas Ramsauer, Product Manager of Division Woodtech, explains: “This development project was all about incorporating advances in digitalization into a tried and tested machine to enhance it and exploit all available technical options for our customers. The result is the DSB Twinhead Pro XM, a future-proof band saw for high-quality thin-cutting of wood.”

The basic version can be extended to three machines in total – connected in series. This amounts to a total of 6 saw modules in one system. Thanks to the dual design of each machine, the DSB Twinhead Pro XM is also a space-saving solution.

SHARE:

Modern solutions for more efficient production processes.

Digitalization brings with it enormous opportunities and possibilities. With so much data available for the cutting process, such as feed speeds for different kinds of wood, it is possible to think in terms of saw blade optimization. Andreas Ramsauer explains: “The last few years have shown us that digitalization has also reached the woodworking industry. So the logical next step was to take up this engineering trend.” The following digital solutions have been implemented with the DSB Twinhead Pro XM:

Digital saw blade detection.

The machine automatically detects and identifies the marked WINTERSTEIGER saw blade at the start, and provides cutting process data, such as the feed speed. The machine and tool data are linked, and a simplified form of tool management can also be realized. Data no longer have to be entered manually – apart from wood type and customer-specific data.

Automatic block width measurement.

The DSB Twinhead Pro XM uses optical sensors to measure the block width, and the customer receives reliable information about throughput, that is, the cut m2.

Automatic bearing monitoring.

Bearing monitoring documents the condition of the bearings, and when sufficient data is available, can anticipate imminent bearing damage. Once wear is ascertained, the preventive replacement of the bearings can be arranged so that it does not interfere with production times.

Connection to the myWINTERSTEIGER cloud.

Production output data (per shift, for example) and tool management are stored in a structured way in the myWINTERSTEIGER cloud, and clearly presented on the dashboard. This valuable information forms the basis for continuous optimization in the production process. The customer’s remote maintenance package automatically includes connection to the cloud.

Specialization: Cutting softwood.

As wood prices rise, high-quality thin cutting is also becoming increasingly important in the softwood segment. This trend was taken up in the machine development, and the new DSB Twinhead Pro XM was optimized for this area of application. Technical improvements include extremely powerful chip extraction, and a faster feed with speeds of up to 45 meters per minute. Andreas Ramsauer on the engineering: “The DSB Twinhead Pro XM is even better at meeting the needs of the softwood sector, and subsequently achieves perfect cutting results. Even customer-specific adaptations do not cause a problem.”

Complex machine, easy handling.

The machine was developed from the operator’s perspective. The user interface has been completely overhauled to make navigation as intuitive as possible. The thin-cutting band saw has a 12-inch multi-touch display and an easily understood menu to guide the operator through the program.

It was extremely important to us that the machine was readily accessible for maintenance and repair work. As Achim Priewasser, an application engineer who was involved in the machine development, confirms: “The new DSB Twinhead Pro XM has gone even further when it comes tohandling and cleaning. High precision cutting results are another major benefit of our new machine. The easy and intuitive operation offered by the touch display is a giant leap forward.”

More than just a thin-cutting band saw.

- It is now possible to conceive automated production facilities, thanks to VAP-WINTERSTEIGER GmbH.

- Everything from a single source: Along with the new DSB Twinhead Pro XM thin-cutting band saw, customers also receive band saw blades developed and manufactured by WINTERSTEIGER, global technical support, and individually customized automation solutions.

- WINTERSTEIGER offers financing options such as rental, leasing/finance partners, or payment by installments.