TRC Panel,

fully automated repair of large panels

TRC Panel, fully automated repair of large panels

Repair of panels, single and multiple boards.

TRC Panel, fully automated repair of large panels

Repair of panels, single and multiple boards.

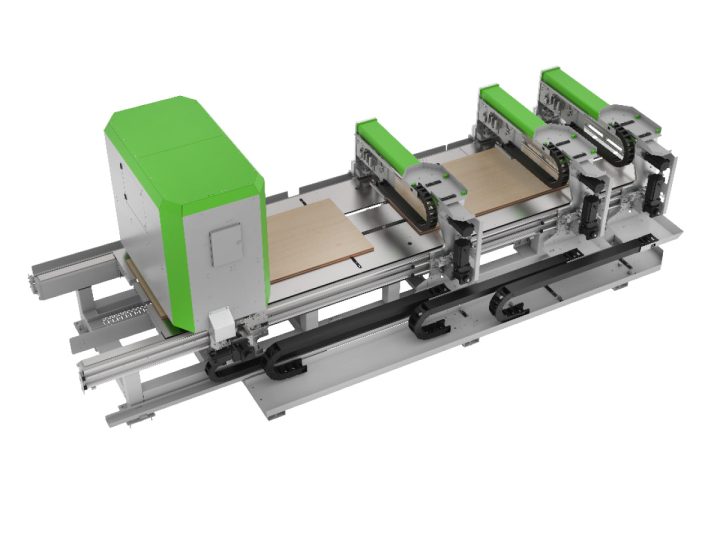

TRC Panel is a modular platform for fully automatic repair of large panels.

Repair with several injection units.

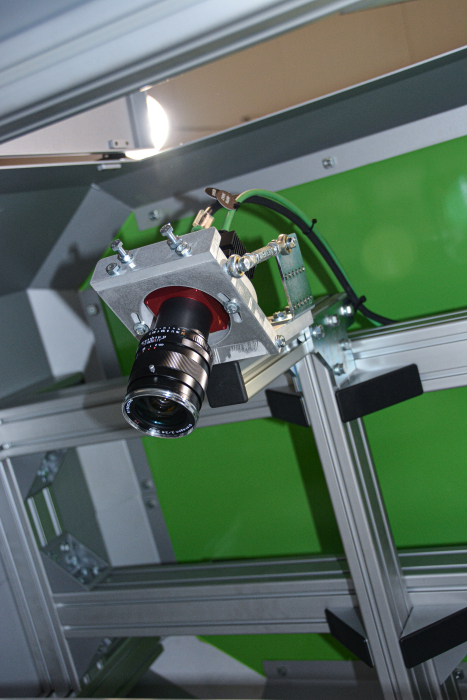

The repair process starts with the panel being scanned. The scanner scans the entire panel in one sweep. As soon as it is finished, it sends the data to the injection units and the defects are repaired in a high-precision process. Only the volume calculated by the scanner is filled into the crack or knothole; the surrounding grain of the wood is not processed.

The repairs can be made in various material colors. It is possible to carry out remote technical support of the TRC system via the internet.

Turning unit.

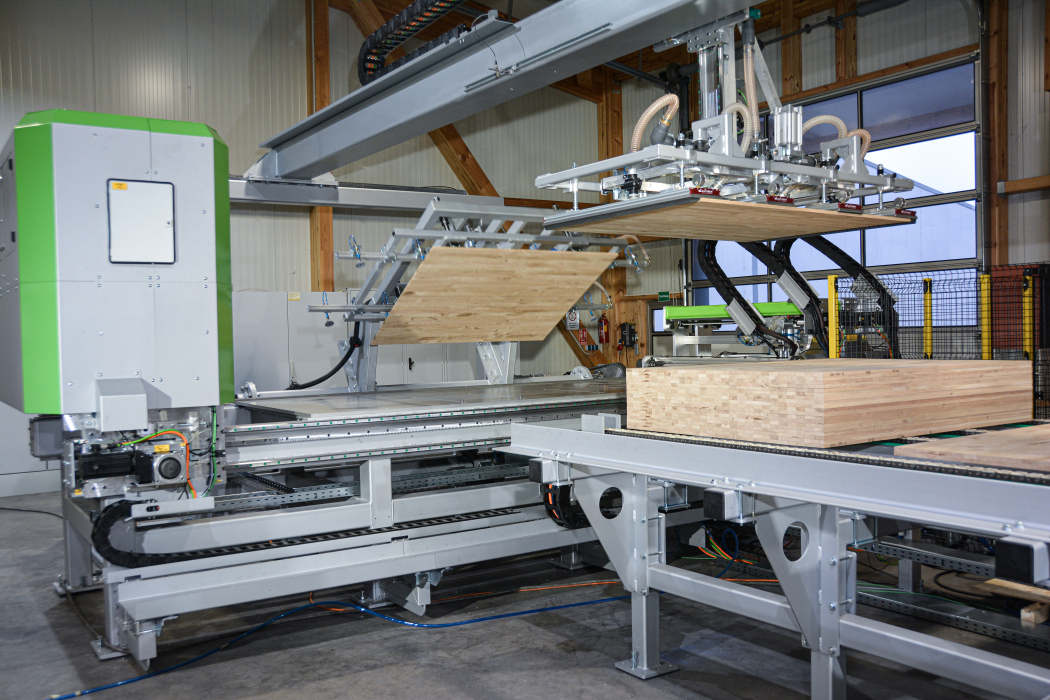

Once the front of the board is completed, the turning unit turns the board 180° and the back undergoes the same process.

Onward transport.

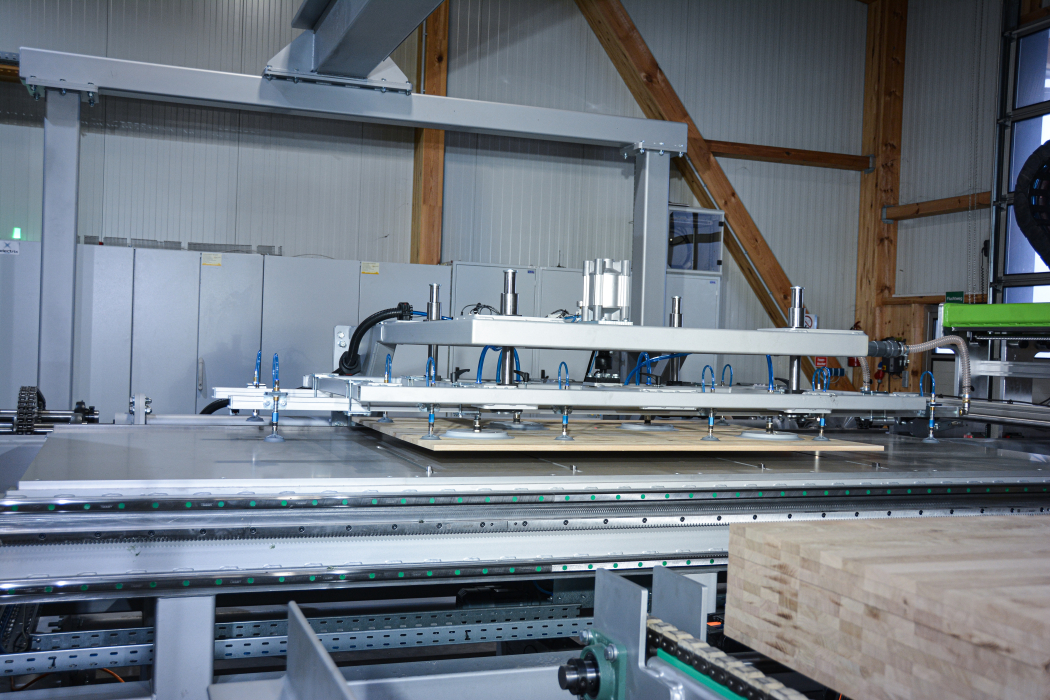

After the board has been scanned, it is transported onwards via a slider in the machining table so that the defects can be processed by the repair unit. This step significantly increases the system‘s capacity as one board is being repaired while the next is being scanned.

Double loading.

As well as machining individual panels and boards, two short boards with a length of around 900 mm to 1500 mm can be placed on the machining table, scanned, and processed in a single step. This increases capacity for short boards.

Control scan.

Once the boards have been repaired, the scan is repeated to check the result of the repair.

Number of repair units.

The number of repair units significantly affects the system capacity and must be tailored to the rustic nature of the goods and the subsequent process steps.

Handling system.

The panel is taken from the stack, repaired, and restacked. Once a panel stack has been completely processed, the system stops, and the repaired stack can be replaced by a new stack.

Random length

The „Random Length“ function allows panels of different lengths to be processed directly one after another without the need for any adjustment.

Options:

In order for us to supply you with the perfect system for all your needs when it comes to capacity, repairs, material flow, and so on, we make use of a modular system with the following options and/or configurations:

| Number of repair units |

|

| Filling material |

|

| Handling system |

|

| Process flow |

|

Application areas:

- Top layers

- Engineered wood flooring

- Multi-strip parquet flooring

- Solid wood flooring

- Multilayer boards

- etc.

Wood dimensions:

- Min. / max. length:

900 mm / 3500 mm (2 units)

900 mm / 2600 mm (3 units) - Min. / max. width: 650 mm / 1300 mm

- Min. / max. thickness: 16 mm / 45 mm

Reference systems

TRC Panel 2TH

Reference systems

TRC Panel 2TH

| Filling material | Thermoplastic (TH) 2 injection units |

| Handling system | Turning unit |

| Process flow | Scanning and touching up in sequence |

| Application | Solid wood panels |

| Panel size | W: 650 mm – 1300 mm L: 900 mm – 3000 mm |

TRC Panel 3OR

TRC Panel 3OR

| Filling material | Organic (OR) 3 injection units |

| Handling system | Onward transport |

| Process flow | Scan and touch up at the same time |

| Application | Multiple boards |

| Panel size | W: 650 mm – 1250 mm L: 900 mm – 2020 mm |

WINTERSTEIGER’s experienced sales staff can help tailor an individual solution to fit your needs!